Bambu Lab PAHT-CF Filament - Black

1kg - 1.75mm - 70100

Bambu Lab PAHT-CF Filament - Black

1kg - 1.75mm - 70100

- Brand: Bambu Lab

- MPN: N04-K0-1.75-1000-SPL

- Part #: INKBAM0164

- UPC:

- Brand: Bambu Lab

- MPN: N04-K0-1.75-1000-SPL

- Part #: INKBAM0164

- UPC:

Features

Specifications

Reviews

Delivery & Pick-up

Returns & Warranty

Popular 3D Printer Filament & Resins

Bambu Lab PAHT-CF Filament - Black 1kg - 1.75mm - 70100

- Brand: Bambu Lab

- MPN: N04-K0-1.75-1000-SPL

- Part #: INKBAM0164

Product URL: https://www.pbtech.co.nz/product/INKBAM0164/Bambu-Lab-PAHT-CF-Filament---Black-1kg---175mm---7

| Branch | New Stock | On Display |

|---|---|---|

| Auckland - Albany | 0 | |

| Auckland - Glenfield | 0 | |

| Auckland - Queen Street | 0 | |

| Auckland - Auckland Uni | 0 | |

| Auckland - Westgate | 0 | |

| Auckland - Penrose | 0 | |

| Auckland - Henderson (Express) | 0 | |

| Auckland - St Lukes | 0 | |

| Auckland - Manukau | 0 | |

| Hamilton | 0 | |

| Tauranga | 0 | |

| New Plymouth | 0 | |

| Palmerston North | 0 | |

| Petone | 0 | |

| Wellington | 0 | |

| Auckland - Head Office | 0 | |

| Auckland - East Tamaki Warehouse | 0 | |

| Christchurch - Hornby | 0 | |

| Christchurch - Christchurch Central | 0 | |

| Dunedin | 0 |

Features

Downloads: Filaments TDS

Bambu Lab PAHT-CF

Product Features:

- Low Moisture Absorption

- Exceptional Mechanical Properties & Layer Adhesion

- High Tensile Strength

- Comes with High Temperature Reusable Spool

- Diameter: 1.75mm +/- 0.03mm

Cautions for Use:

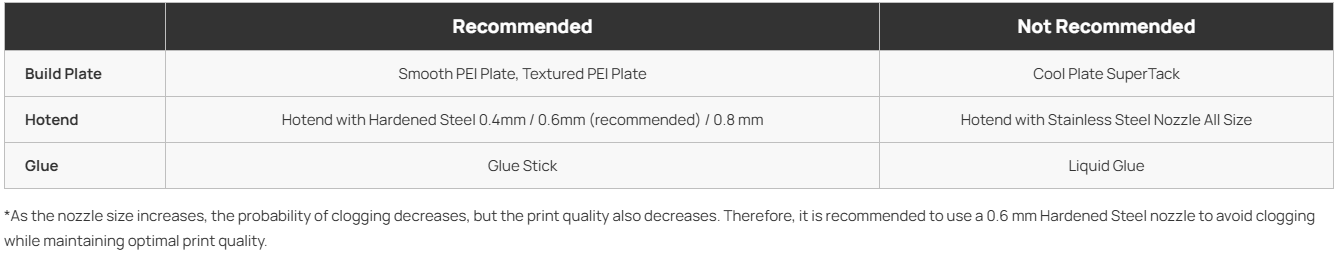

- 0.6 mm Nozzle Recommended

- 0.2 mm Nozzle NOT Compatible

- Stainless Steel Nozzle Not Recommended

- Dry before Use for the Highest Print Quality

- AMS 2 Pro, AMS HT & AMS Compatible

- AMS lite NOT Compatible

- Dry before Use for the Highest Print Quality

- Enclosure Printer Required

Note: PAHT-CF is an upgraded version of PA-CF (PA-CF was discontinued).

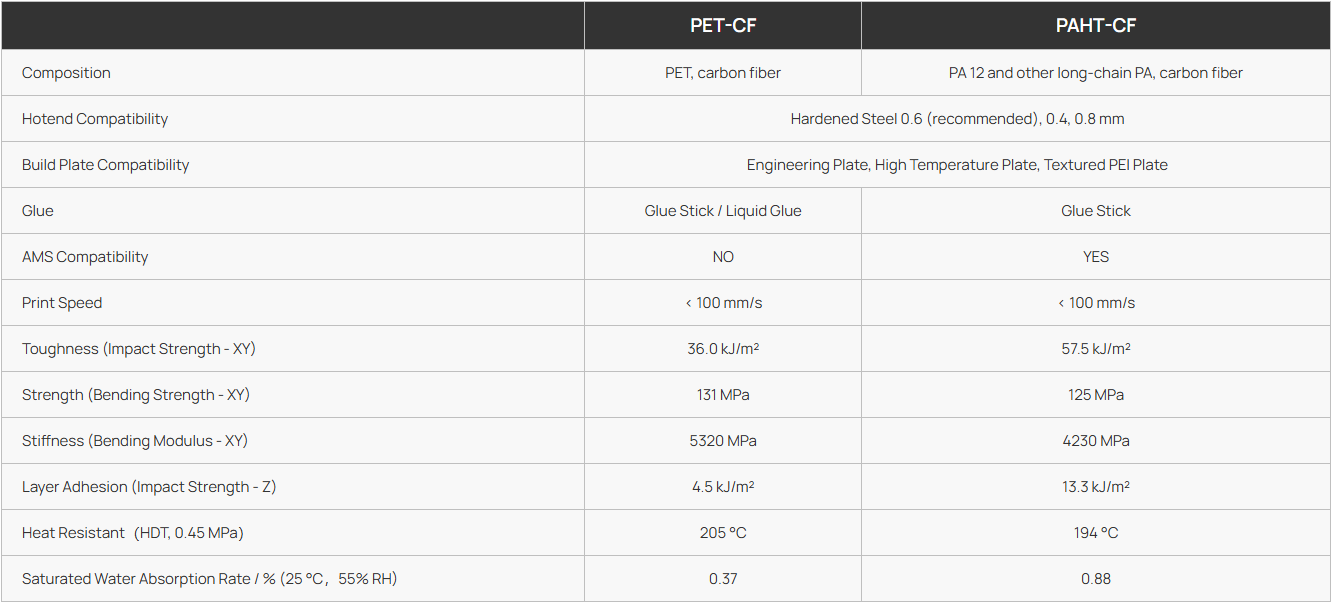

Bambu PAHT-CF

Bambu PAHT-CF is a composite of PA12 and carbon fiber. Inheriting the advantages of low water absorption from PA12 and high-performance carbon fiber, Bambu PAHT-CF offers excellent mechanical and thermal properties that can be maintained well even when the prints get wet. Higher Z adhesion layers and flexibility make it ideal for creating engineering parts such as functional prototypes, machining fixtures, injection molds, jigs, and low-volume production parts.

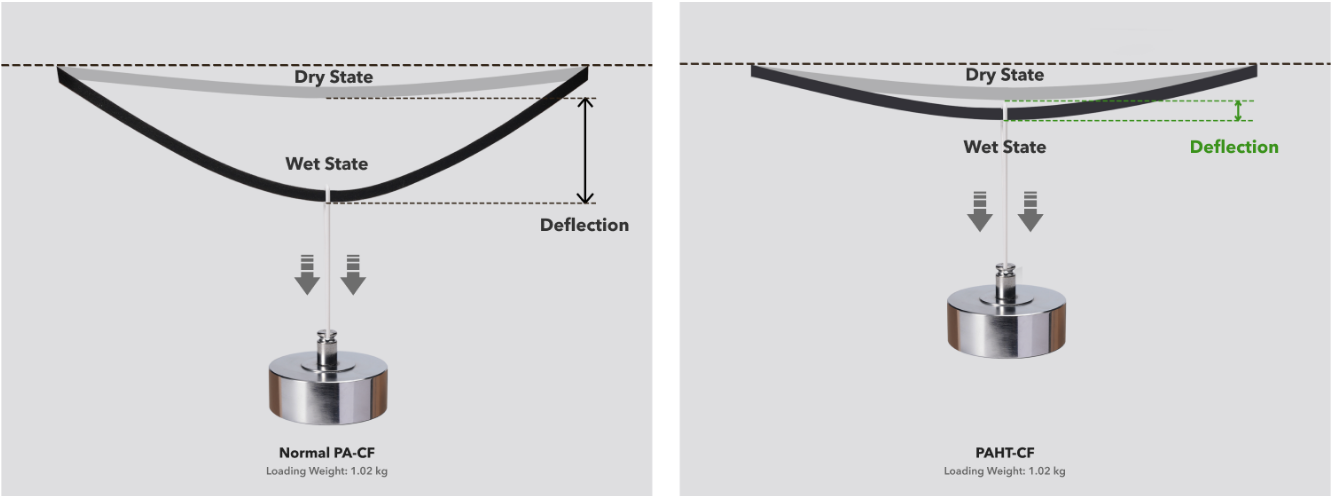

Low water absorption

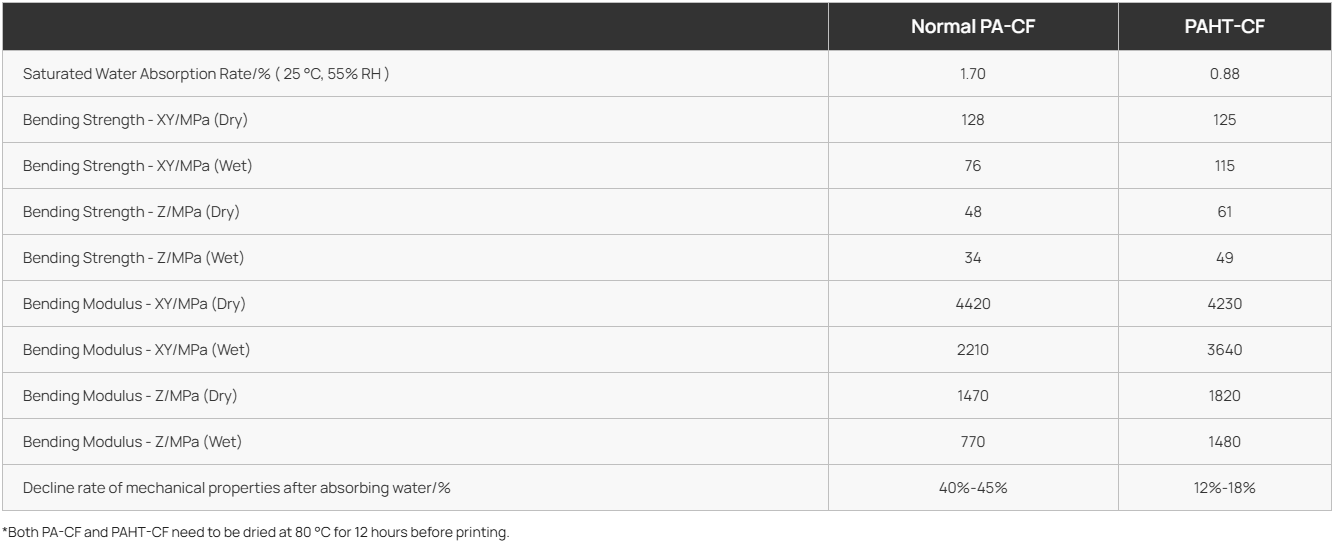

With a 50% lower water absorption rate compared to normal PA-CF,

Bambu PAHT-CF maintains excellent mechanical properties and dimensional stability even when exposed to high humidity.

Deflection from Dry to Wet

Mechanical Properties Comparison

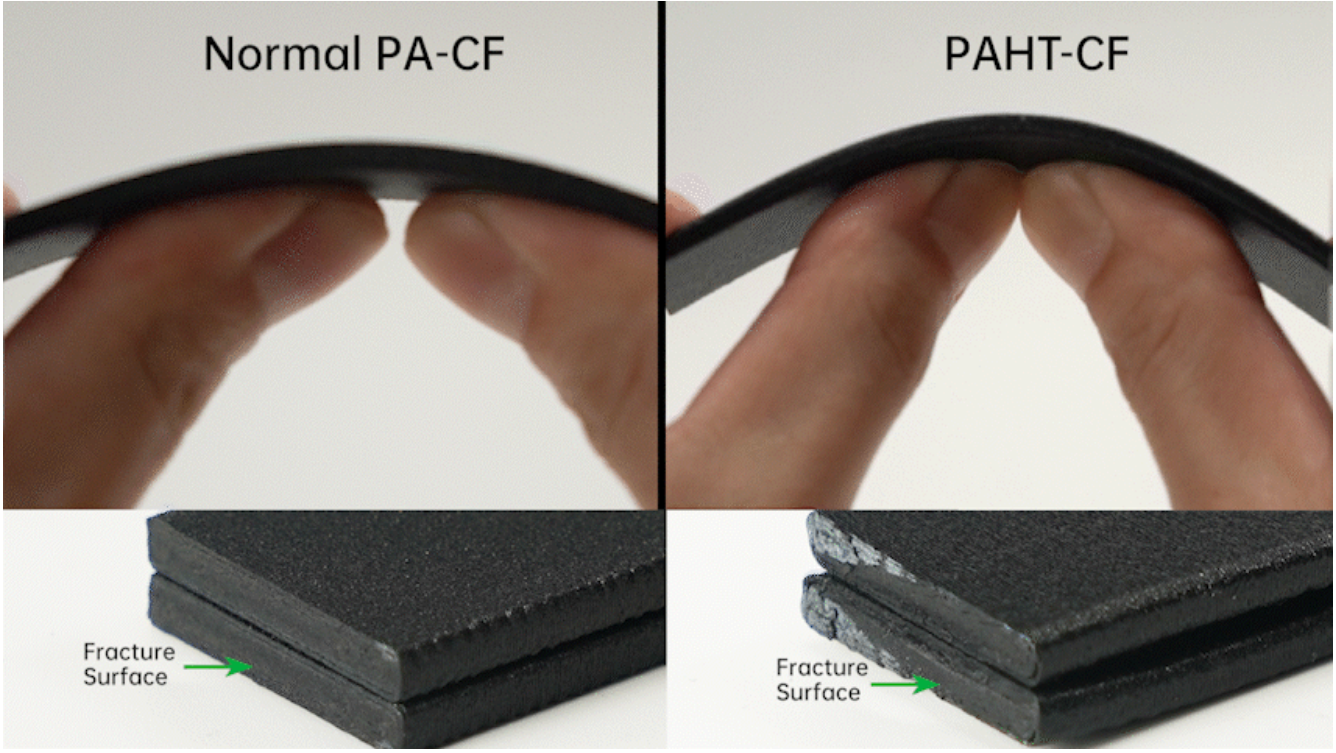

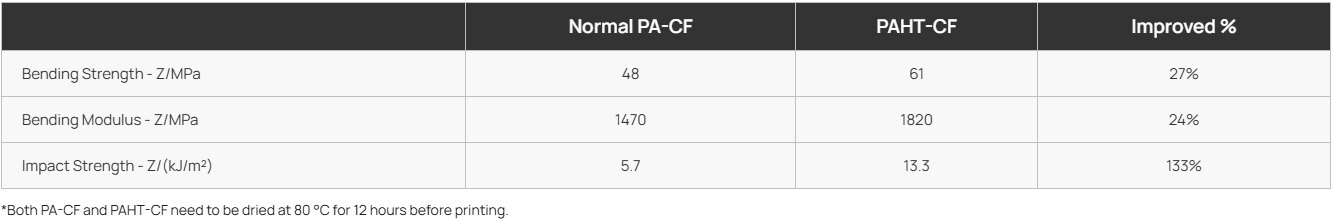

Exceptional Z-bonding

Bambu PAHT-CF shows much higher adhesion in Z layers compared to normal PA-CF,

bringing it the ability to withstand high levels of impact or stress without breaking or deforming.

Z-layer Performance

High tensile strength

Bambu PAHT-CF is designed to meet the demands of various industrial

and engineering applications where high strength and durability are required.

Designed for high-temperature resistance

The heat deflection temperature of Bambu PAHT-CF is up to 194℃ (0.45MPa)*, making it useful in applications where the printed parts may be exposed to high temperatures without deforming or losing their strength.

*The long-term temperature resistance is related to the structure and usage scenario of the model itself.

Accessory Compatibility

RFID for Intelligent Printing

All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System).

Load and print! No more tedious setting steps.

Parameters Comparison

Learn more different filaments comparison on Bambu Filament Guide >>

Printing Tips

- Drying conditions: 80℃ for 8 hrs. PAHT-CF is highly sensitive to humidity. To achieve optimal printing performance, it is recommeded further drying before use and after storage. For more details please refer to: Filament drying instructions on WIKI.

- Bambu PAHT-CF has high thermal insulation requirements during the printing process, making it unsuitable for use with open-frame printers.

- When printing a model with support, we recommend removing the support structures within 2 hours after printing to prevent them from sticking after absorbing moisture. If sticking occurs, dry the model to ease the removal.

- For better print results, please refer to: Printing tips for Engineering materials on WIKI..

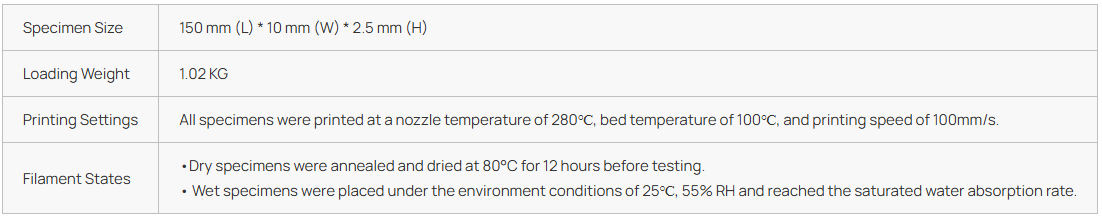

*Test Conditions

Specifications

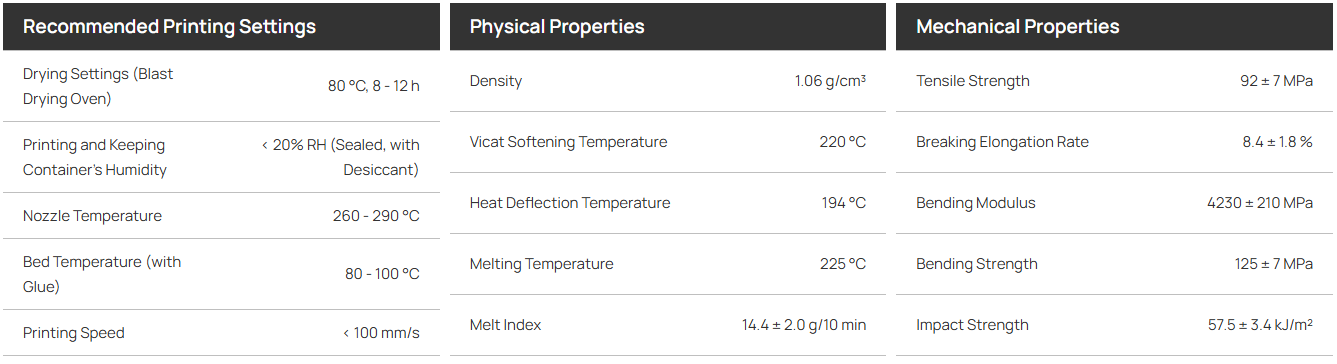

Recommended Printing Settings

Drying Settings (Blast Drying Oven)

80 °C, 8 - 12 h

Printing and Keeping

< 20% RH (Sealed, with Container's Humidity Desiccant)

Nozzle Temperature

260 - 290 °C

Bed Temperature (with Glue)

80 - 100 °C

Printing Speed

<100 mm/s

Physical Properties

Density

1.06 g/cm3

Vicat Softening Temperature

220 °C

Heat Deflection Temperature

194 °C

Melting Temperature

225 °C

Melt Index

14.4 + 2.0 g/10 min

Mechanical Properties

Tensile Strength

92 + 7 MPa

Breaking Elongation Rate

8.4 + 1.8 %

Bending Modulus

4230 + 210 MPa

Bending Strength

125 + 7 MPa

Impact Strength

57.5 + 3.4 kJ/m2