Bambu Lab H2SL Full Combo

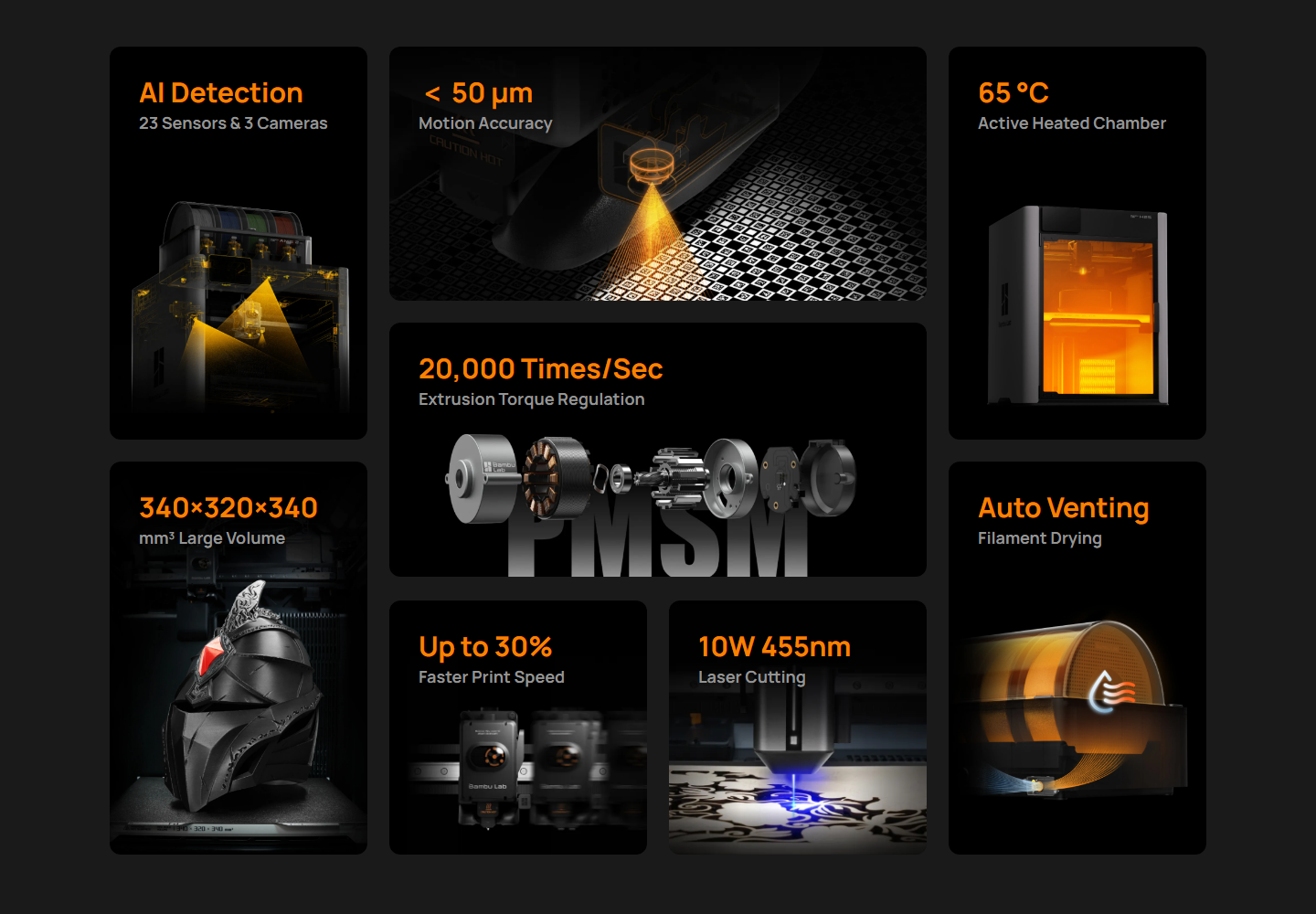

with 10W Laser and Cutting Module, Build Size 340 x 320 x 340mm - Automatic Material System - Multi-Colors / Materials Capability - Up to 16 Multi-Color Printing

Bambu Lab H2SL Full Combo

with 10W Laser and Cutting Module, Build Size 340 x 320 x 340mm - Automatic Material System - Multi-Colors / Materials Capability - Up to 16 Multi-Color Printing

- Brand: Bambu Lab

- MPN: PF003-L+SA007-AU

- Part #: PTRBAM0020

- UPC:

Select your store to check availability

- Brand: Bambu Lab

- MPN: PF003-L+SA007-AU

- Part #: PTRBAM0020

- UPC:

Features

Specifications

Reviews

Delivery & Pick-up

Returns & Warranty

Popular 3D Printers

Bambu Lab H2SL Full Combo with 10W Laser and Cutting Module, Build Size 340 x 320 x 340mm - Automatic Material System - Multi-Colors / Materials Capability - Up to 16 Multi-Color Printing

- Brand: Bambu Lab

- MPN: PF003-L+SA007-AU

- Part #: PTRBAM0020

Product URL: https://www.pbtech.co.nz/product/PTRBAM0020/Bambu-Lab-H2SL-Full-Combo-with-10W-Laser-and-Cutti

| Branch | New Stock | On Display |

|---|---|---|

| Auckland - Albany | 1 | |

| Auckland - Glenfield | 1 | |

| Auckland - Queen Street | 2 | |

| Auckland - Auckland Uni | 0 | |

| Auckland - Westgate | 2 | |

| Auckland - Penrose | 2 | |

| Auckland - Henderson (Express) | 0 | |

| Auckland - St Lukes | 1 | |

| Auckland - Manukau | 0 | |

| Hamilton | 0 | |

| Tauranga | 0 | |

| New Plymouth | 0 | |

| Palmerston North | 1 | |

| Petone | 1 | |

| Wellington | 1 | |

| Auckland - Head Office | 5 | |

| Auckland - East Tamaki Warehouse | 0 | |

| Christchurch - Hornby | 0 | |

| Christchurch - Christchurch Central | 1 | |

| Dunedin | 1 |

Features

Please Note: The filaments in the pictures above are sold separately

Bambu Lab H2S

Your Personal Manufacturing Hub

Accuracy That Works for You - Correct Mechanical Deviations

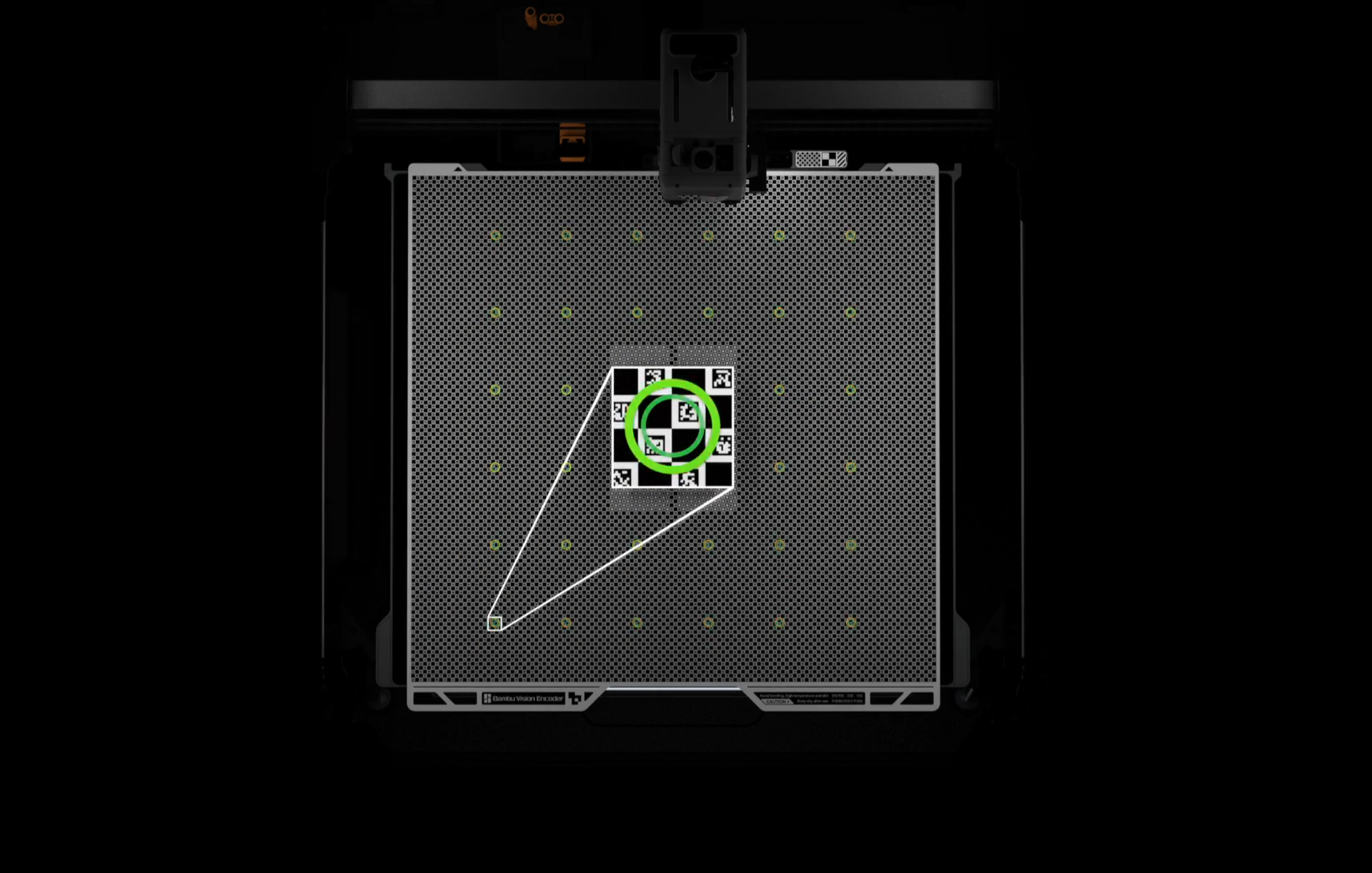

Even the printer comes out of the factory with superb accuracy, mechanical wear and variances over time are inevitable-but now, first time in the industry, there's a solution.With the Vision Encoder⁽¹⁾, the H2S achieves distance-independent motion accuracy under 50 μm-thinner than a human hair. During calibration, it automatically compensates for mechanical drift, ensuring consistent precision and peak performance over time.

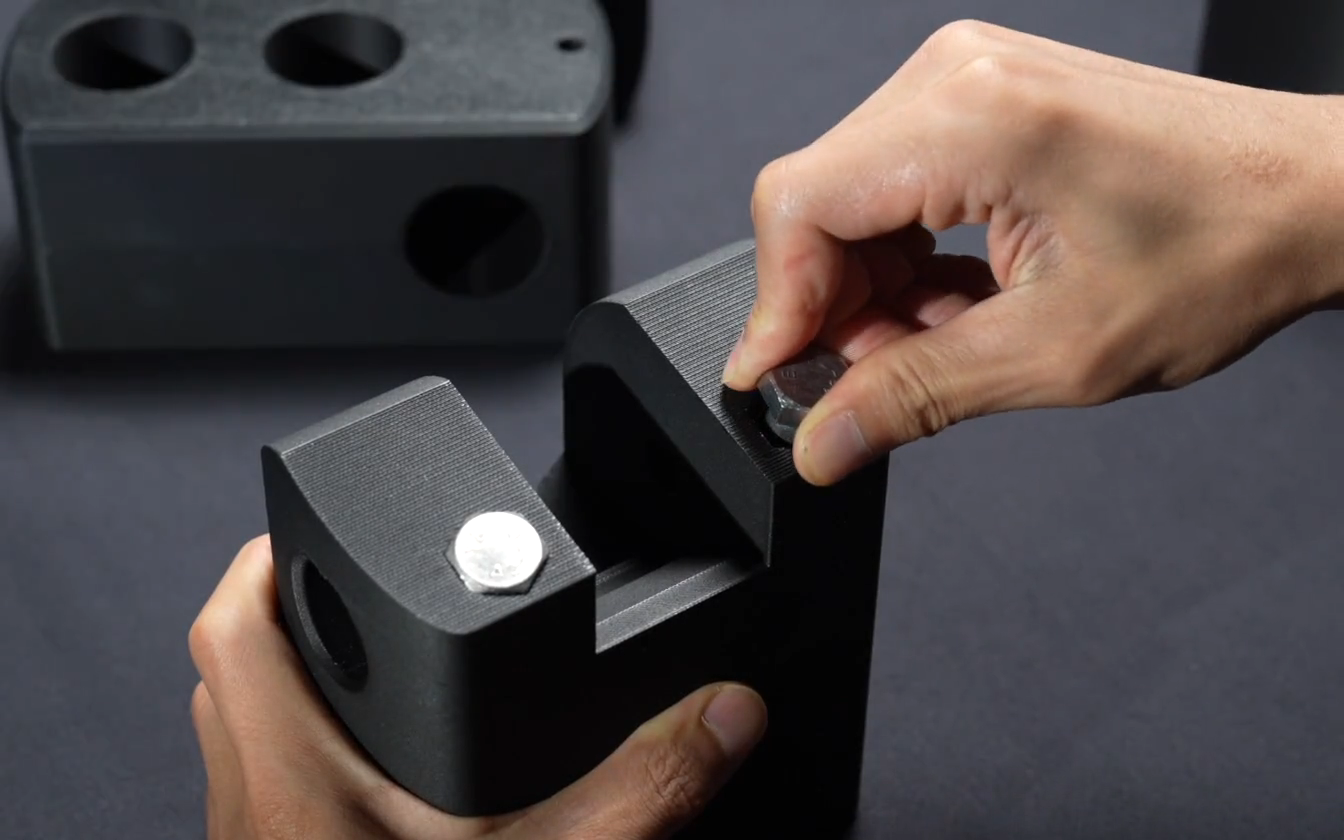

One Print. Perfect Fit.

Bambu Lab's Auto Hole/Contour Compensation⁽²⁾ minimizes printing tolerances, delivering machine-shop-level precision for hole dimensions. Design fit-critical parts with confidence-integrate shafts, bearings, and fasteners without trial and error. Post-print assembly has never been easier.

Ready for Engineering Filaments

Featuring a 350 °C hotend and a 65 °C actively heated chamber, it supports the entire Bambu filament lineup-from PLA and PETG to PC and PPA. With closed-loop fan control and precise thermal management, the H2S minimizes warping and deformation while improving layer adhesion. Build large, high-performance parts that are as functional as they are strong.

350 °C Hotend

65 °C Heated Chamber

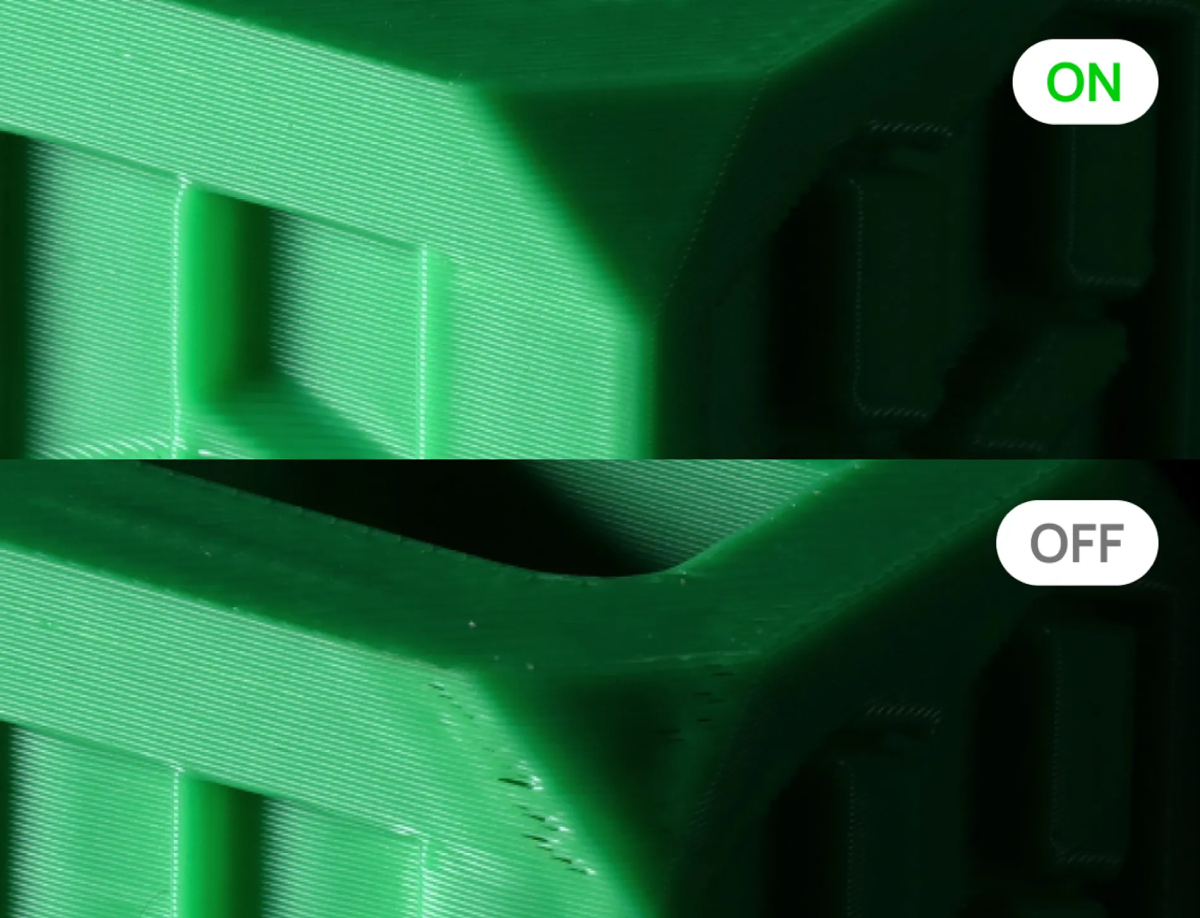

Even Surfaces, Crisp Edges

H2S uses both the sensing capability of its servo motor on the extruder and the high-resolution eddy current sensors on the nozzle to precisely control extrusion by measuring nozzle pressure and calibrating PA parameters for each filament, improving surface smoothness and edge sharpness.

Precision in Motion

Active Vibration Compensation neutralizes micro-vibrations and resonance in real time, enabling premium print quality at higher speeds.

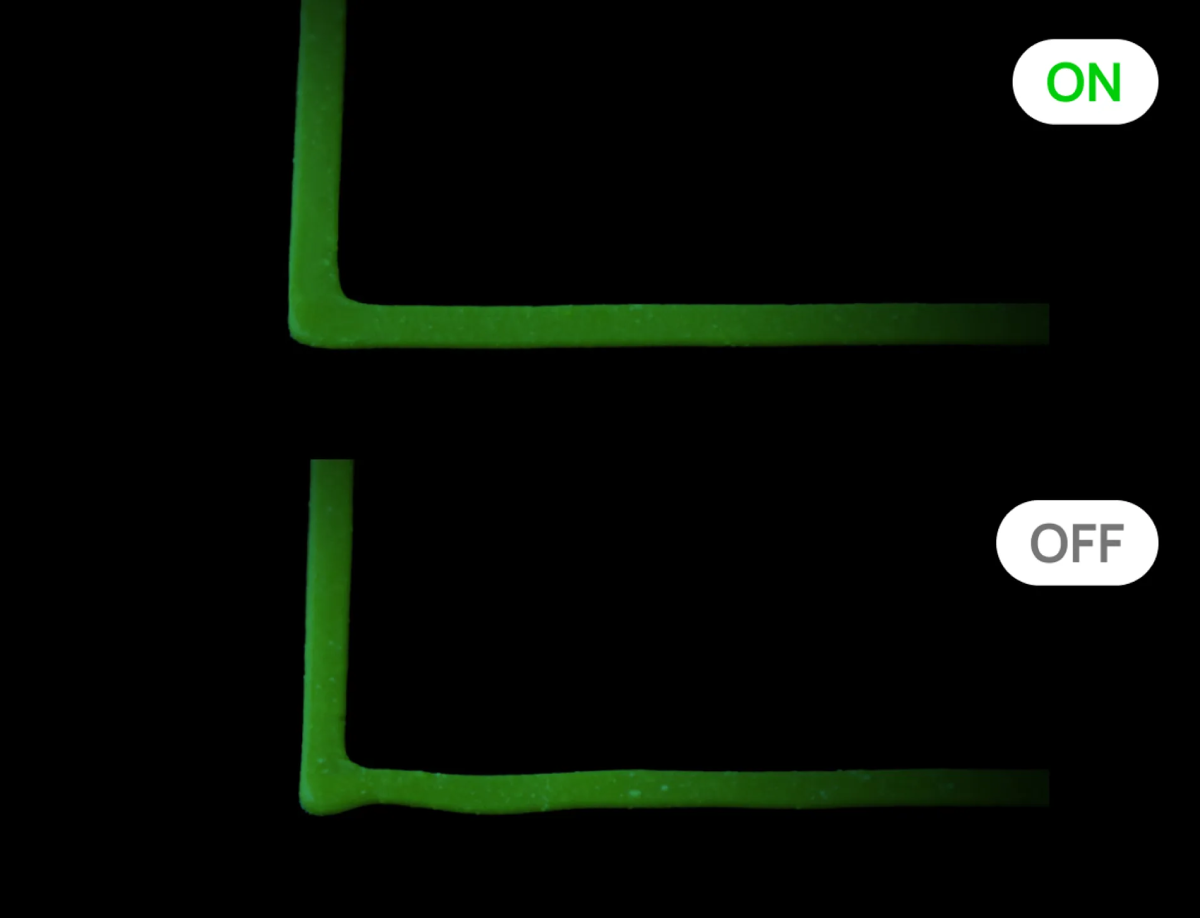

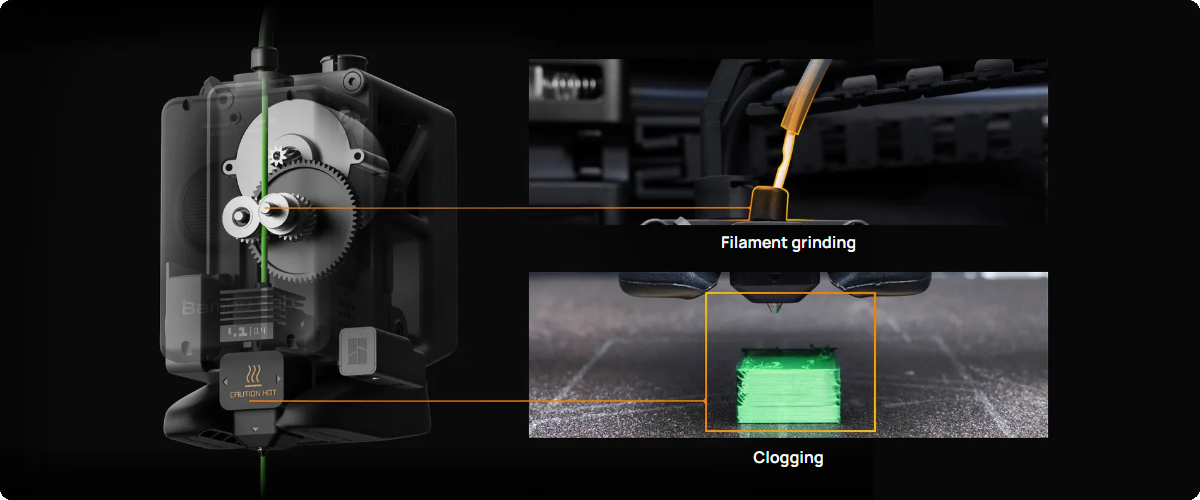

Intelligence That's Got Your Back - 20,000 Checks Per Second - Closed-Loop Feedback, Real-Time Control

Bambu Lab's proprietary PMSM servo system enables 20 kHz resistance and position sampling to dynamically modulate electromagnetic torque vectors. It stabilizes extrusion and actively detects grinding⁽³⁾ or clogs in real time.

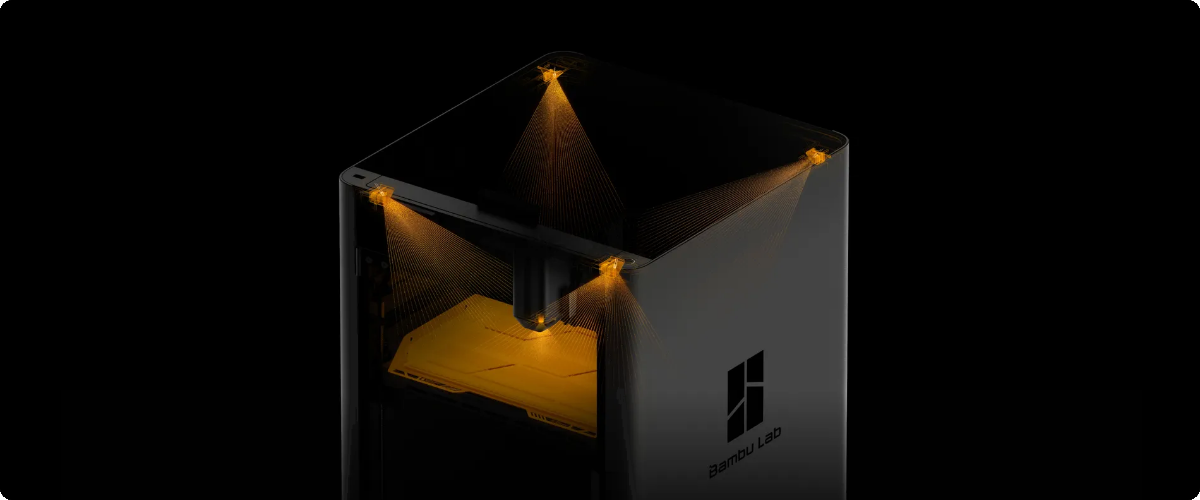

23 Sensors + 3 Cameras - Each Potential Risk Has Its Own Detector

Vision System

With AI-driven real-time monitoring, the vision system detects clumping, spaghetti and purge chute jamming as they happen, helping prevent failed prints before they start. This same vision system powers advanced features like Live Spatial Alignment, allowing precise laser and cutting calibration, and Vision Encoder technology, which enhances positional accuracy.

Feeding

Filament-path sensors work in unison to monitor feeding speed and position, detect filament tangles and grinding risks, track filament mileage and spool usage, and ensure tool readiness across the AMS, buffer, cutter, and feeding paths, making sure every tool is in place and every move is under control.

Thermal Control

Five NTC temperature sensors are strategically placed across the nozzle, heatbed, and chamber. Paired with integrated airflow sensors, the system actively monitors and adjusts internal temperatures and circulation, maintaining the ideal print environment through real-time feedback control.

Safety

The H2S features five flame sensors, front-door and top-cover sensors, and emergency stop button to form a complete safety system. It detects fire risks, monitors enclosure alignment, and allows instant shutdown when needed-protecting your projects and your workspace at all times.

Pre-Flight Checklist by AI

Prior to each operational cycle, the H2S vision system initiates a comprehensive pre-flight checklist: Chamber Integrity Scan - Detects debris across the entire print surface. Hardware Configuration Audit - Instantly identifies build plate properties.

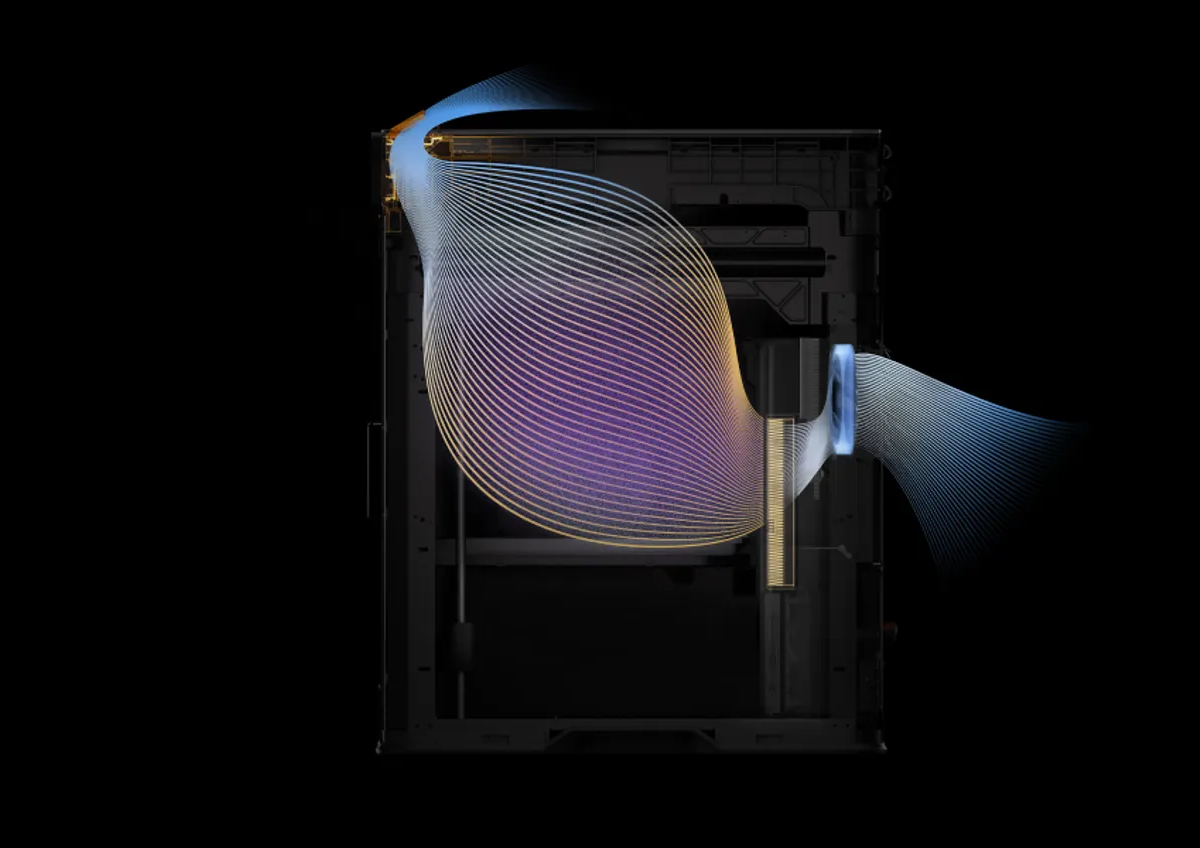

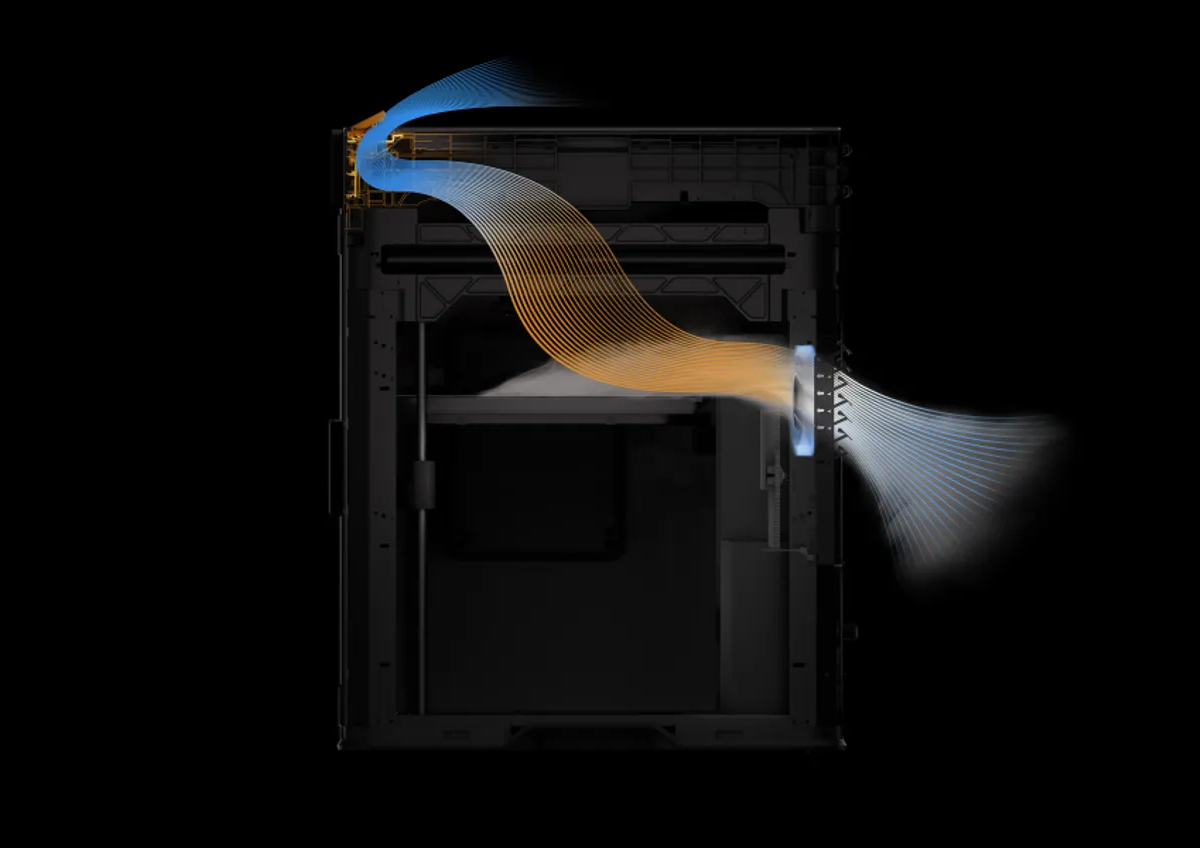

Flap Switch Airflow & Filtration System - 3D Printing & Laser Cutting. 3 Modes, All-in-One

High-Temp Printing

Chamber sealed. Internal air recirculates through the Air Filter and the heater to stabilize high-temp conditions. Print large engineering parts without warping.

Low-Temp Printing

Top Vent opens to bring in cool air, while maintaining a filtered exhaust⁽⁴⁾. Print PLA and PETG without opening the door, and handle overhangs and bridging with ease.

Laser Cutting/Engraving

Top Vent and Filter Switch Flap open. Fumes are channeled efficiently to the ventilation system, keeping your workspace safe and clean.

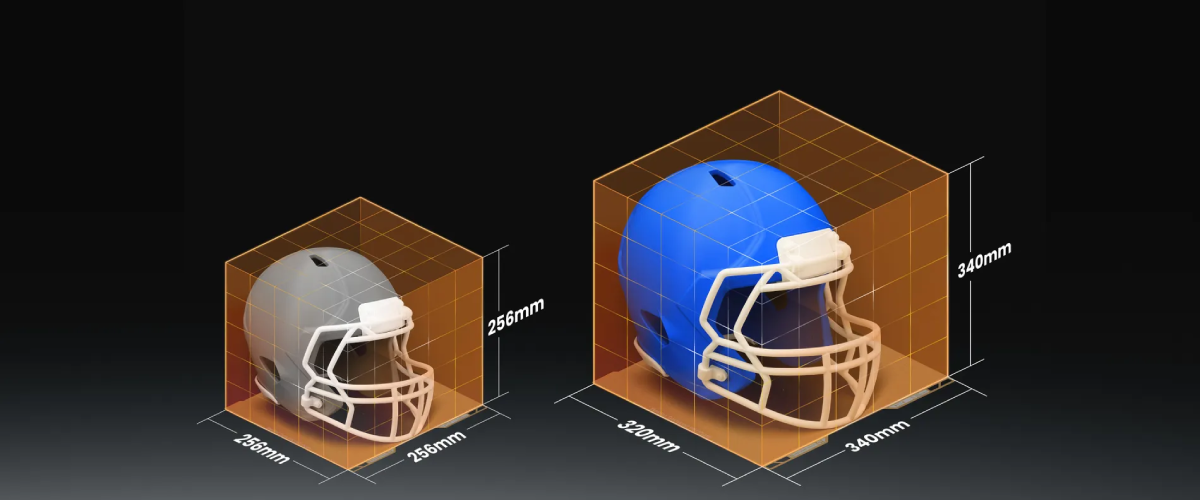

Bigger. Faster. Better. Maximum Volume. Maximum Productivity.

With a build volume of 340x320x340 mm³, the H2S offers the largest print space among all Bambu Lab printers. Your Vision. Fully Realized in One Print.

120% Larger Build Volume

Than the X1 Carbon

Full Scale Printing

Print bigger, with fewer plates

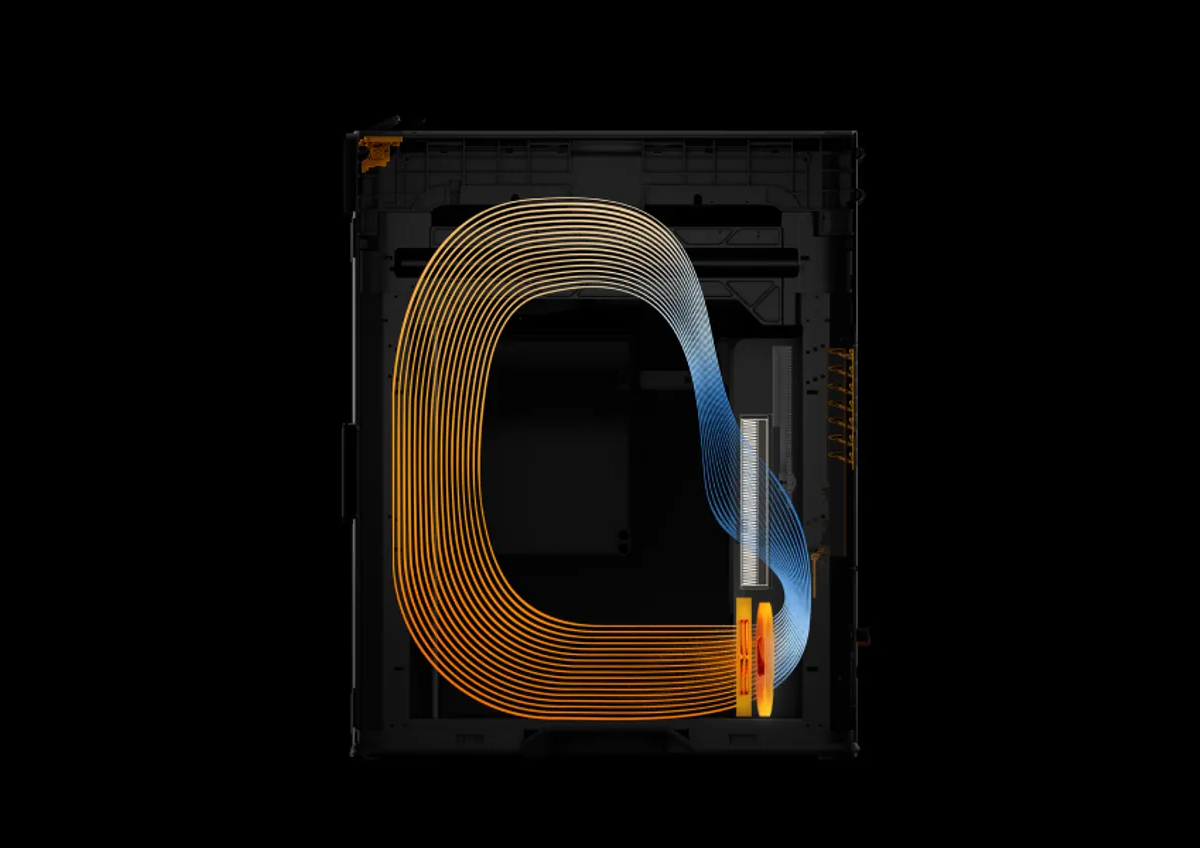

Top Speed. More Reliable Than Ever.

Bambu Lab's proprietary PMSM⁽⁵⁾ servo extrusion system delivers 67% more extrusion force, providing solid support to high flow⁽⁶⁾ printing. Paired with up to 1000 mm/s toolhead speed and up to 20,000 mm/s² acceleration, your H2S can finally go full throttle-cutting your printing time by up to 30%⁽⁷⁾-while maintaining top-tier quality.

DynaSense Extruder

PMSM servo extruder delivers up to 10kg of extrusion force-67% more than regular stepper motors, delivering the strongest support for high-flow printing.

Cut. Engrave. Draw. Compact. Capable. All in One.

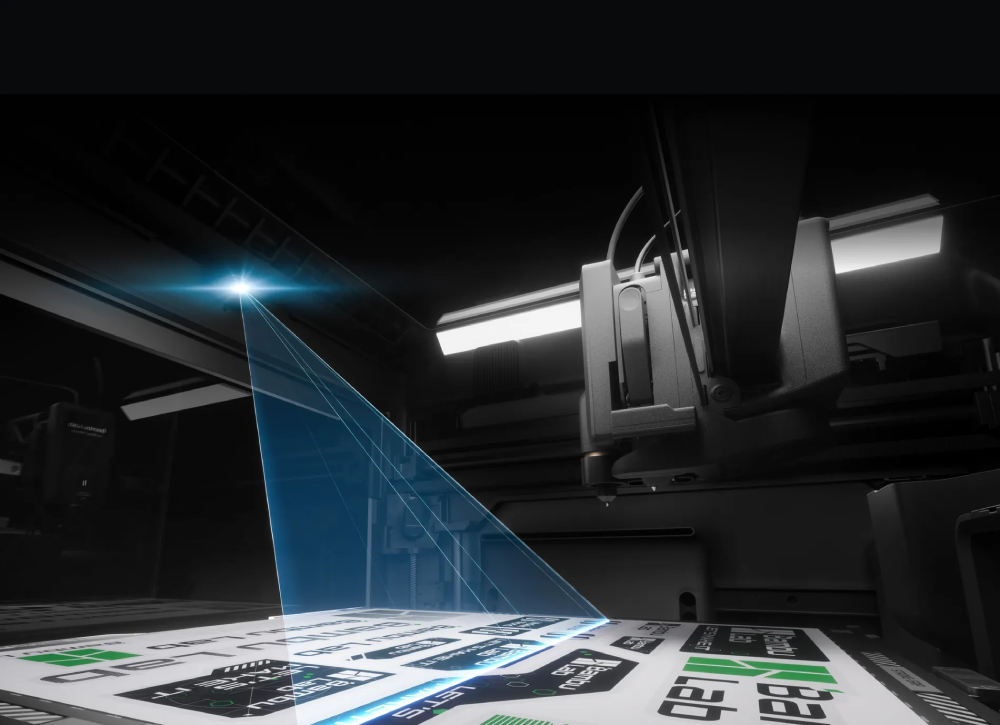

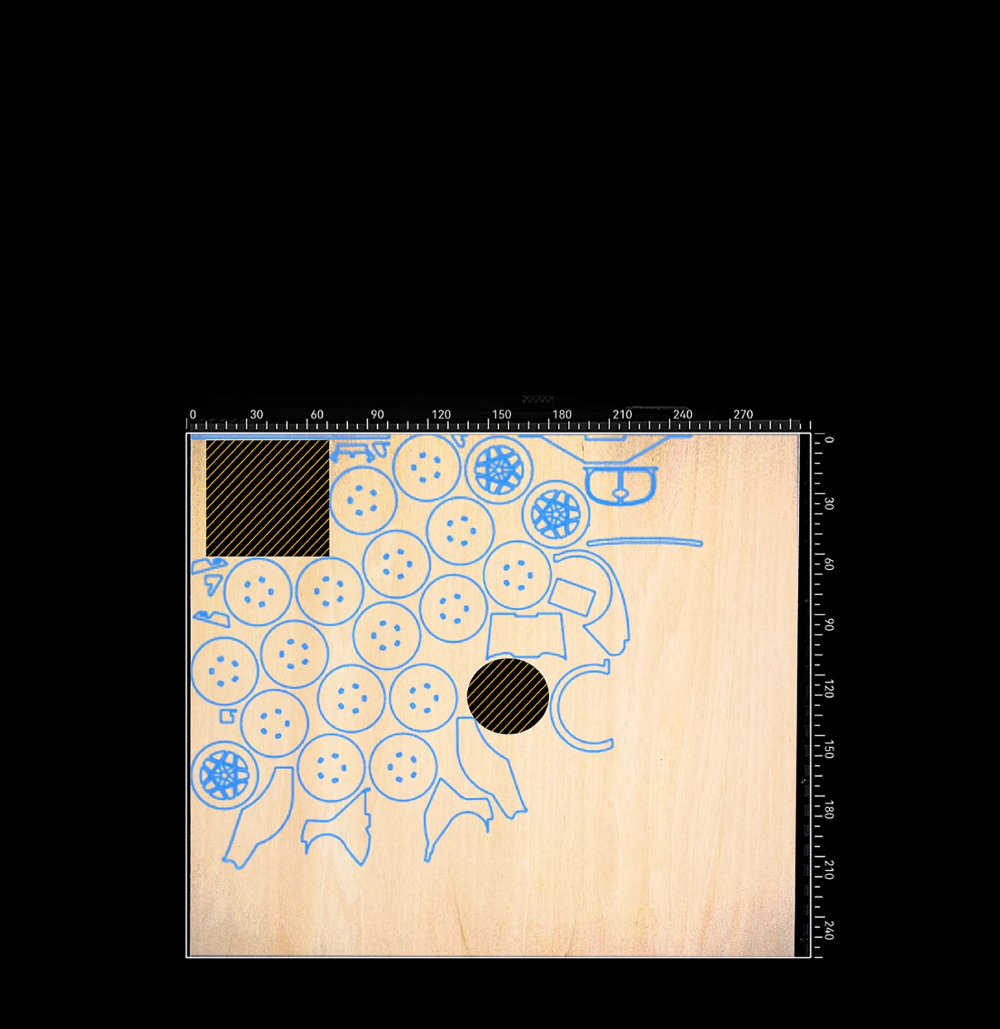

Live Spatial Alignment

Top-down BirdsEye camera⁽⁸⁾ and onboard toolhead camera enable Live Spatial Alignment, letting you preview the toolpath directly on your material with 0.3 mm accuracy. What you see is what you get.

Auto Arrangement

Bambu Suite automatically arranges your project shapes to make the most of every sheet-smart, efficient, and effortless.

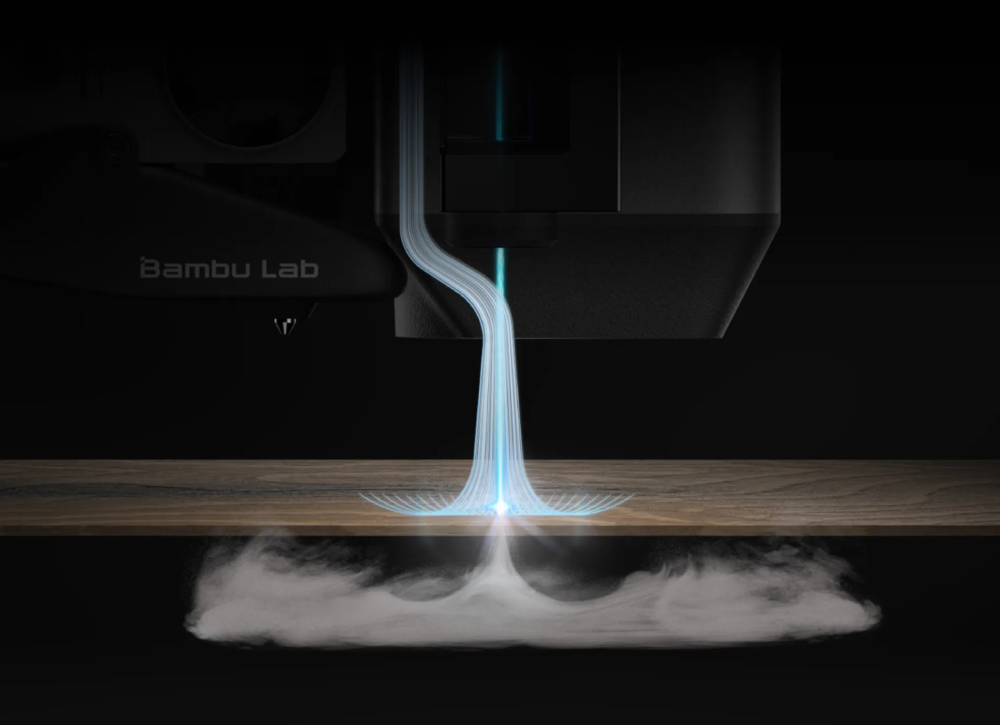

10W 455nm Laser Power

Slice through up to 5 mm plywood, acrylic, or PU with ease-clean, fast, and precise.

Air Assist

Air Assist keeps your lines crisp by blowing away smoke and char while cooling the surface-preventing soot buildup and beam distortion for sharp, clean results.

Digital Cutting

Effortlessly cut through paper, vinyl, PU leatherette, and more-clean, accurate, and ready to apply.

Drawing

Use the drawing module to automate linework, sketches, or handwritten notes-precise, repeatable, and hands-free.

Protected Inside and Out - Safety, Built In

Laser Safety Window

Shields your eyes from the 455 nm laser beam while keeping your workspace clear and visible.

Five Flame Sensors

Advanced sensors continuously monitor for fire risks. If an issue is detected, a loud buzzer and mobile alert⁹ notify you immediately-so you can act fast and stay safe.

Flame-Retardant Chamber

Constructed with fire-resistant materials throughout, the chamber provides passive protection for added safety.

Emergency Stop

Immediately halt operations if something feels off-giving you full control and added peace of mind.

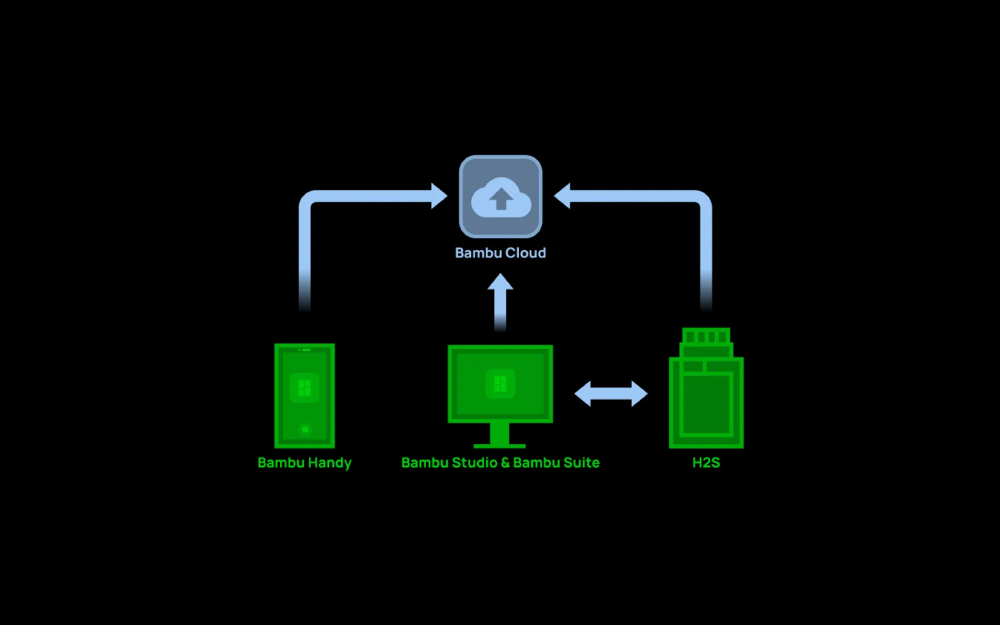

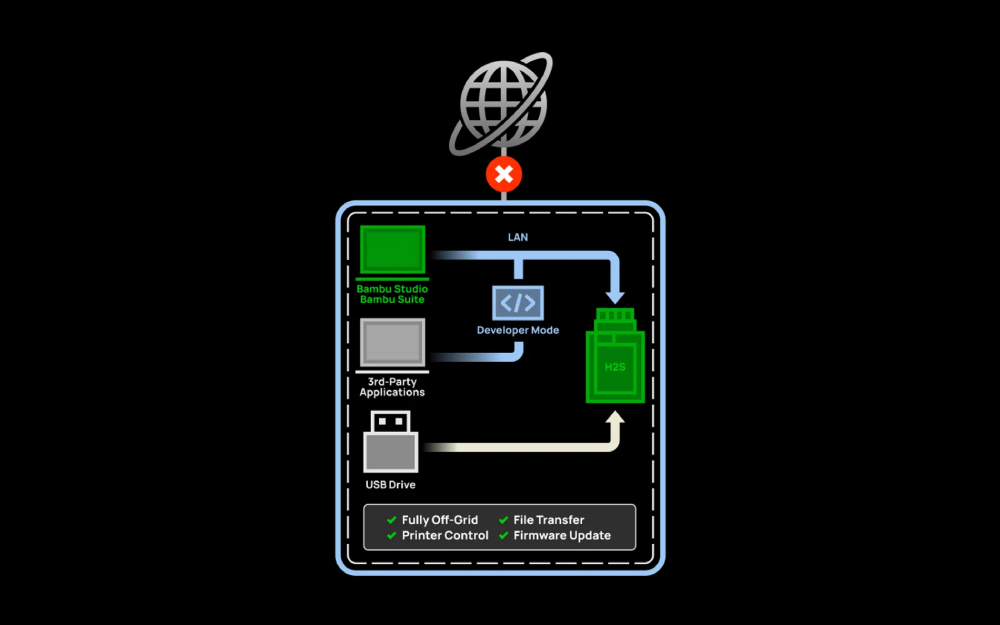

Connectivity, By All Means. Privacy, By Design.

The H2S offers seamless cloud connectivity for convenient remote control from any device. For security-sensitive applications, it also delivers complete offline functionality, ensuring physically isolated operation. Users can control the printer, send files, and upgrade firmware-no internet required. Additionally, Developer Mode unlocks MQTT port access, empowering developers and integrators to connect third-party components and custom software with ease.⁽¹⁰⁾

Accessible. Comfortable. Made to Last.

Quick-Swap Nozzle

Swap nozzles in seconds-no tools, no hassle. Whether you're switching materials or upgrading to a different nozzle size, the redesigned hotend makes it easy and intuitive, even for first-time users.

Quiet by Design

With Active Motor Noise Canceling and specialized air duct noise-reduction technology, the H2S operates below 50 dB⁽¹¹⁾. Print overnight or in shared spaces without disrupting your environment.

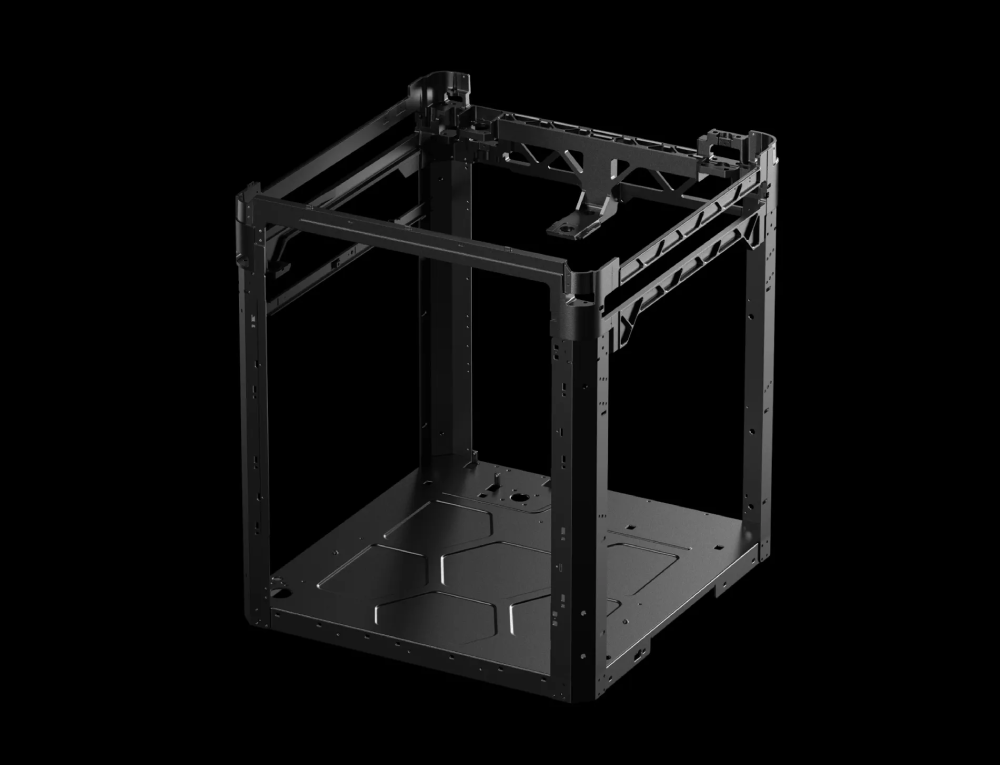

All-Metal, Die-Cast Body

The integrated die-cast aluminum alloy chassis delivers a sturdy, stable structure that provides a rigid foundation for high-speed, large-format printing, while minimizing accuracy loss caused by micro-twisting.

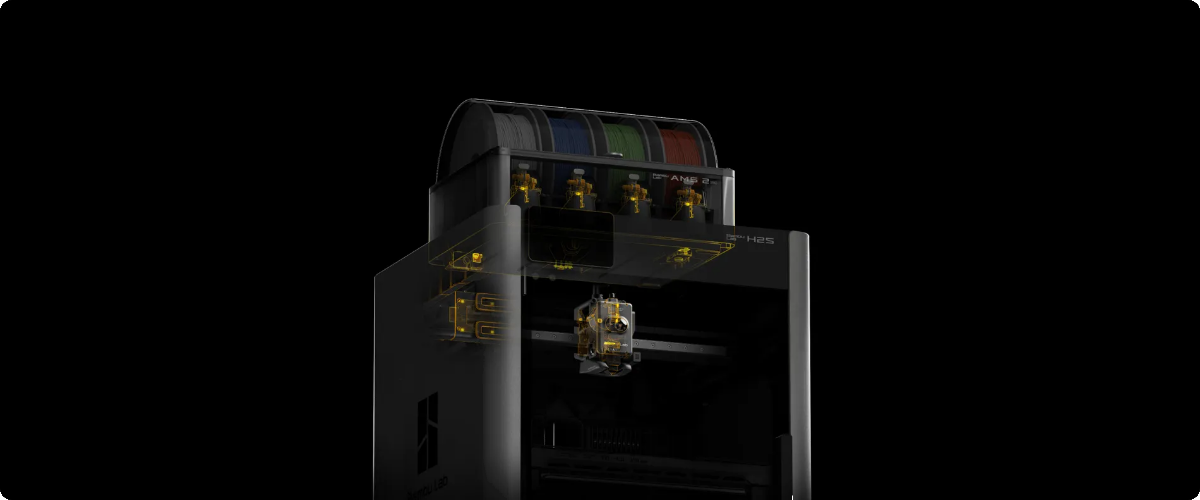

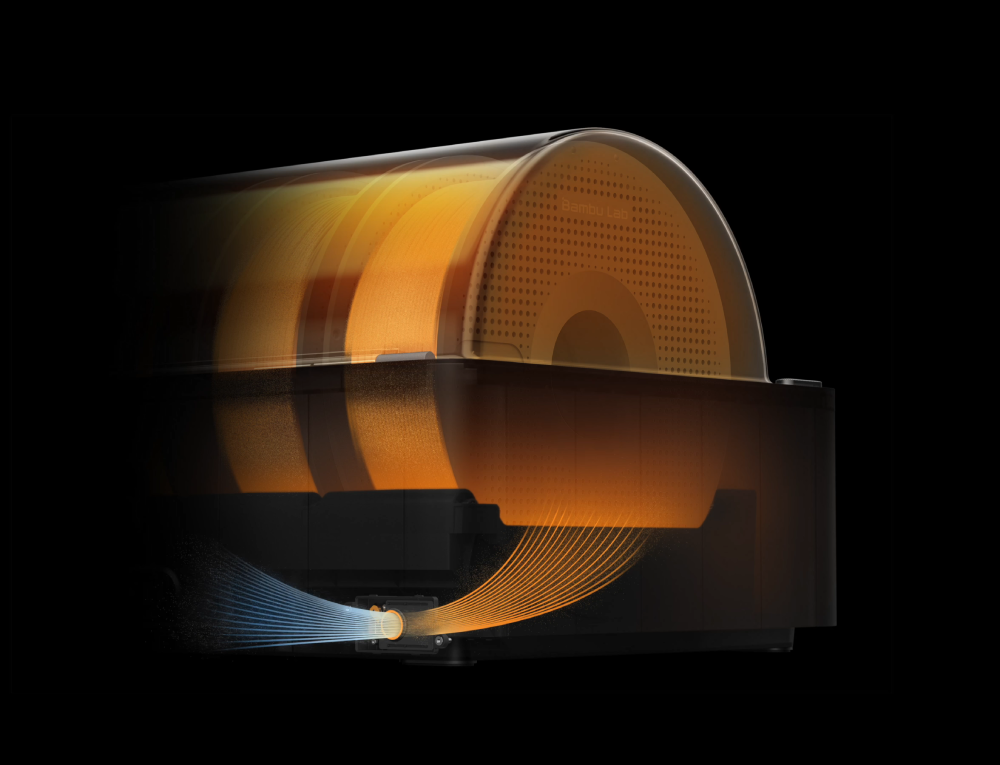

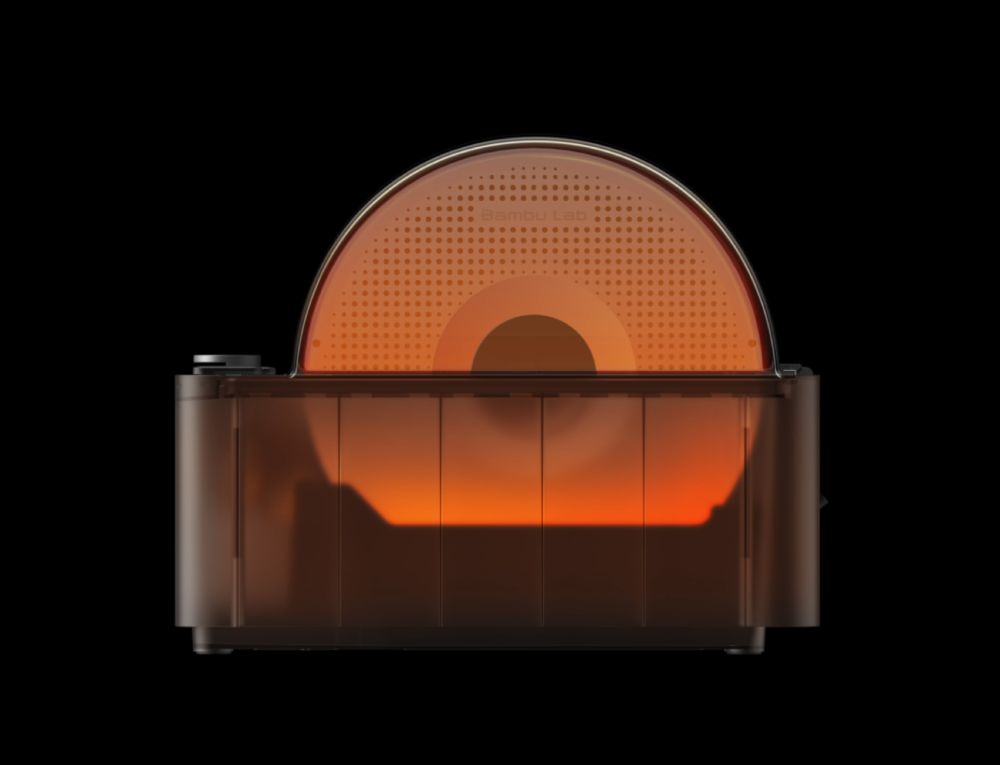

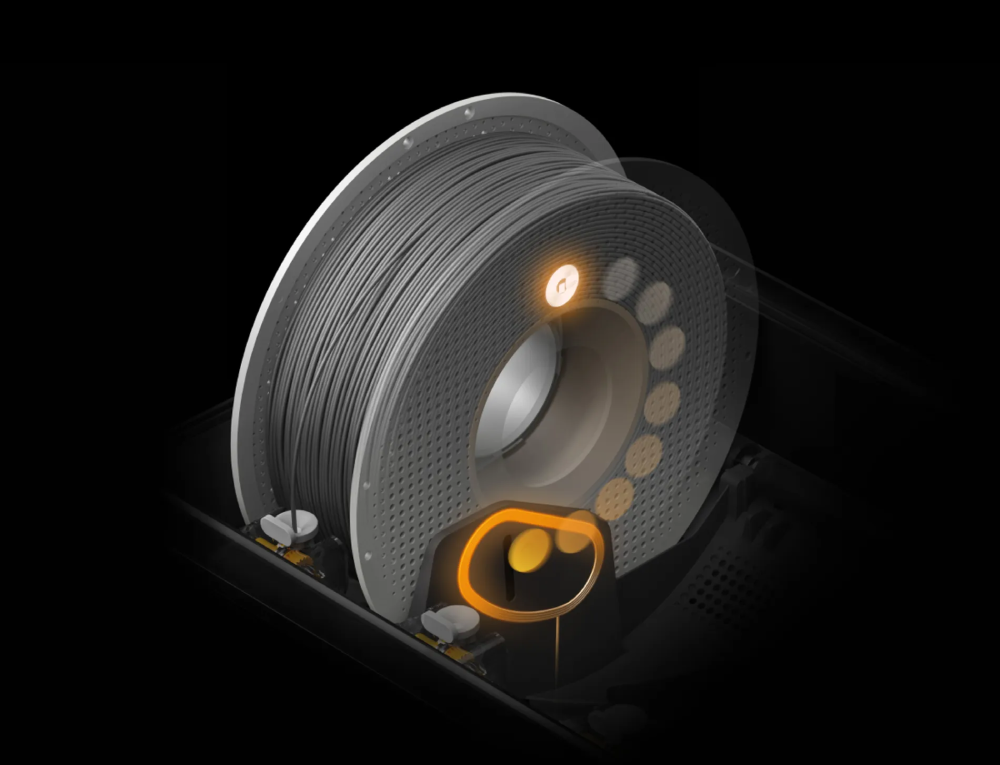

Multi-Color Printing and Drying, All-in-One

Electro-Magnetic Air Vent

Automated venting facilitates dehumidification during drying and airtight sealing for weeks of quality printing.

Auto-Rotate Drying

During the drying process, the filament spools rotate automatically to provide more even drying.

RFID Sync

AMS 2 Pro uses RFID to auto-match drying settings for Bambu official filaments, no manual input needed.

MakerWorld - Ready-to-print Models at Your Finger Tips

On MakerWorld, you'll find an endless supply of great models, all ready for your H2S. With seamless integration, you can skip the hassle of figuring out settings or slicing. The perfect print profiles for your specific printer and filaments are already in place. Simply hit print and get started! This kind of effortless printing is standard on MakerWorld, so you'll always have something new to try, and your printer can keep busy!

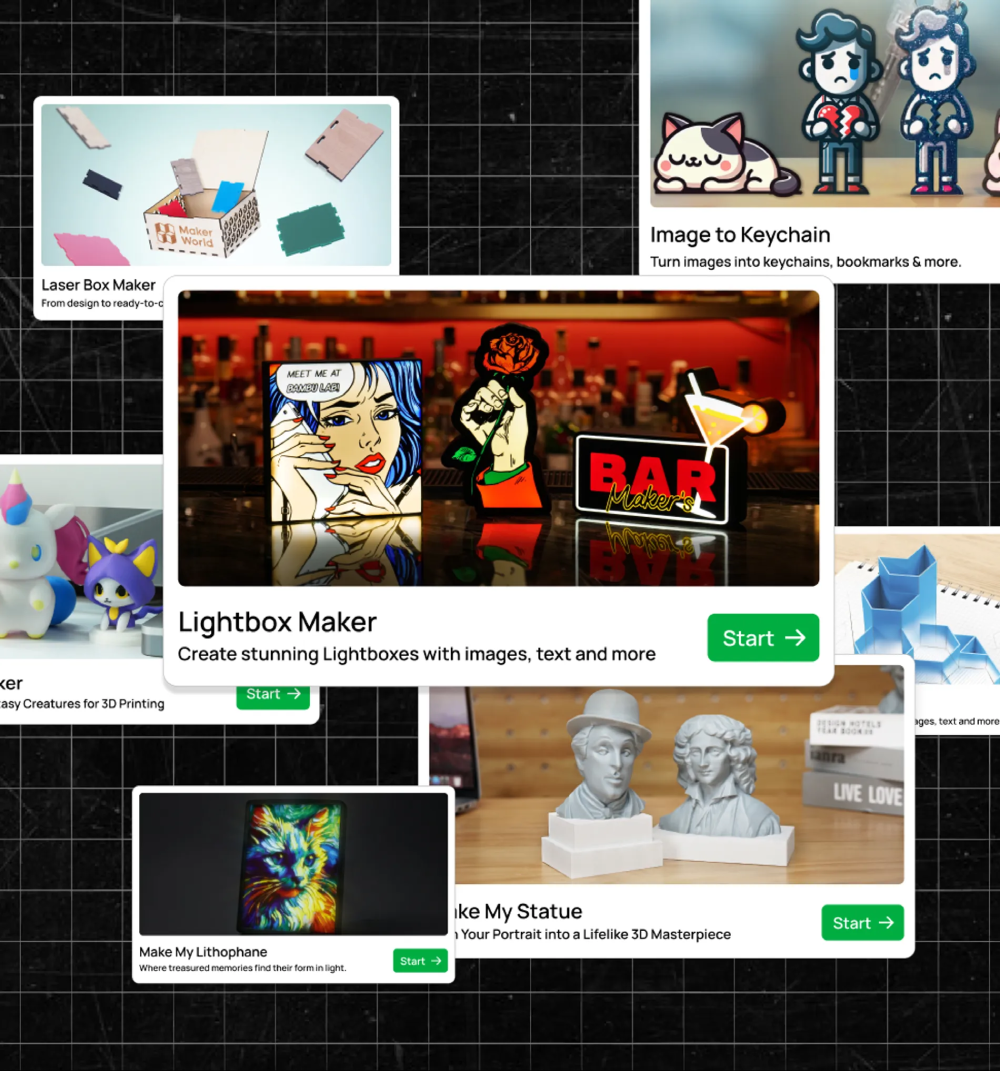

MakerLab - AI Assisted 3D Modeling Tools, Bring Your Vision to Life

Transform your favorite artwork into a personalized lightbox, turn a beloved photo into a relief sculpture, or create one-of-a-kind PrintMon figurines from a simple prompt. With Bambu Lab MakerLab, you can design and customize without any 3D modeling skills. Create a bookmark with your favorite anime characters, or an organizer tailored to your desk, with the perfect spot for sticky notes. Whatever you envision, you can create.

Maker's Supply - Go-To Source for Parts that Bring 3D Prints to Life

Maker's Supply provides all the non-3D printed hardware you need for your projects, from motors and LEDs to bolts and magnets. Every pre-tested kit precisely matches the Bill of Materials (BOM) for your chosen MakerWorld project. Just print, assemble, and enjoy!

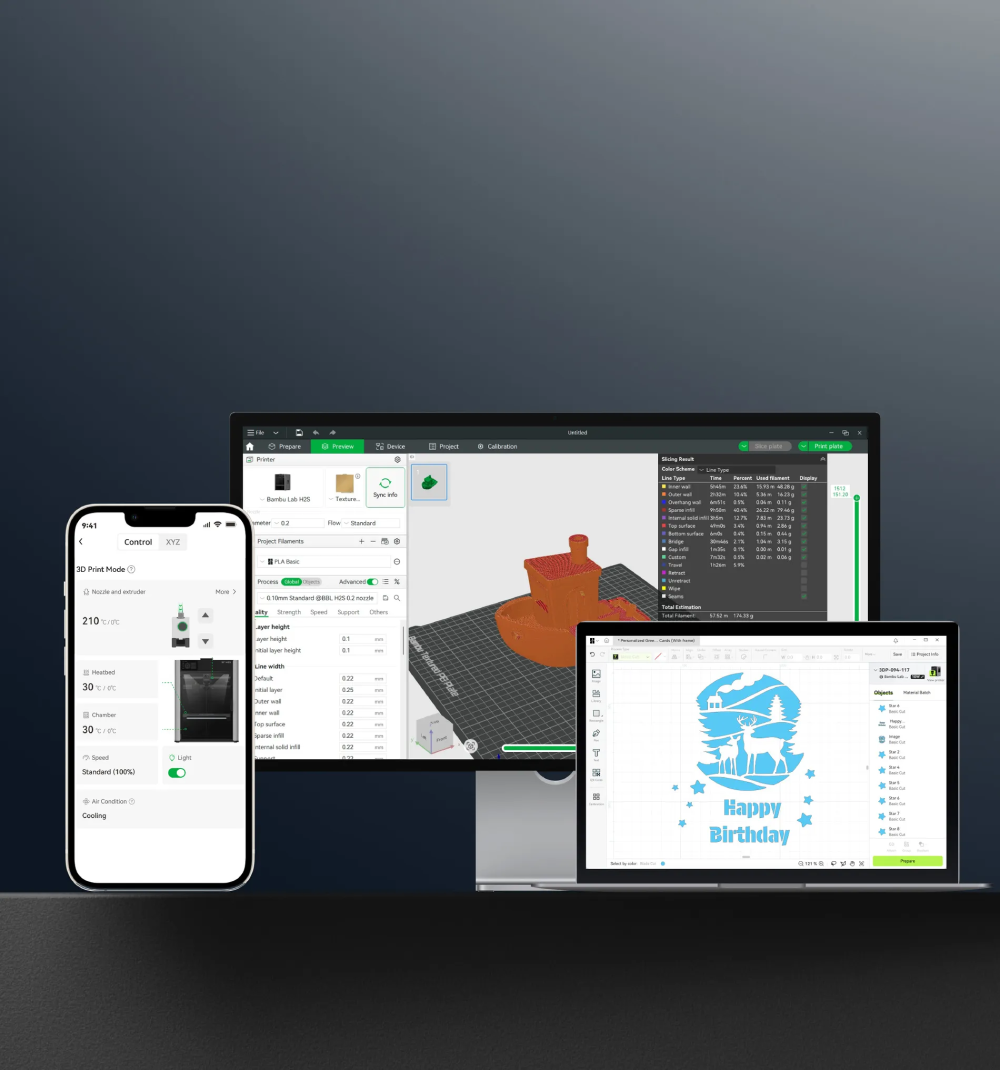

Software Ecosystem - Control Browse From Any Device, Anywhere

Bambu Studio, Bambu Handy, and Bambu Suite create a seamless ecosystem, letting you manage and control your printer, and browse MakerWorld content from anywhere, on any device. Our integrated account system links all your activities, so you never have to worry about losing progress when switching devices or locations.

Bambu Lab Academy - Master Your Printer with Easy-to-follow Lessons

Whether you're just starting your 3D printing journey or aiming for professional mastery, Bambu Academy offers tailored lessons for you and your specific printer model. Our carefully designed curriculum caters to all skill levels, helping you quickly gain knowledge and know-how to make the most of your printer.

Bambu Lab Wiki - Find Answers to Every Printing Problem

No matter what problem you encounter, you can find the answer here. From handling nozzle clogging and filament clumping to maintaining worn printer parts, Bambu Lab Wiki offers step-by-step guides with clear instructions and helpful graphics. Whether you're troubleshooting or simply want to understand your printer better, you'll find the detailed guidance here.

1. Vision Encoder: Vision Encoder needs to be purchased separately on the Bambu Lab Store.

2. Auto Hole/Contour Compensation: Auto Hole/Contour Compensation must be enabled in Bambu Studio and requires the use of designated Bambu filaments.

3. Filament grinding detection on the DynaSense Extruder may vary depending on filament type.

4. Filter Mode for low-temperature printing is optional and will be available in Q4 2025.

5. Permanent Magnet Brush-less Servo Motor

6. High Flow Hotend are optional equipment and can be purchased from the official store.

7. When using Bambu Lab PLA Basic to print a 200×200×200 mm cube with 15% infill, the printing time can be reduced by up to 30% compared to Bambu Lab X1C. Actual time savings may vary depending on the model, infill, and filament used.

8. The laser and digital cutting functions are all controlled and visualized through Bambu Suite. Live Spatial Alignment is enabled by the BirdsEye Camera. The BirdsEye Camera comes standard with the H2S Laser Edition, or can be added via the Laser Upgrade Kit.

9. Push notifications require the use of Bambu Handy and cloud connectivity.

10. Due to safety protocol, Developer mode cannot be enabled when using Laser and Cutting functions.

11. Background noise: 40 dB; Test distance: 1 m

12. The go-kart frame shown in the picture is merely a component of the complete vehicle. Its usability and durability are limited by the overall design and construction of the vehicle. It cannot be used on the road until permission is obtained from the local relevant authorities. When conducting any operations, please strictly abide by the applicable local laws, regulations and safety standards to avoid risks or damages.

13. Creator projects are provided for illustrative purposes only. Bambu Lab does not endorse, and disclaims any representations or warranties regarding creator projects, including, without limitation, the safety, marketability, or usability of any 3D printed works based on such projects. See our Terms of Service for more information.

14. Ensure that a person must be present at all times to closely monitor the machine during laser engraving and cutting operations. Do not open the laser safety window while the machine is operating. The laser process should only be observed through the designated laser safety window. Individuals with medical conditions or sensitivities (e.g., to strong light or smoke) must strictly follow professional medical advice before operating or approaching the machine. For safety instructions regarding laser use, refer to the Laser Module Safety Guidelines Wiki and the Laser Safety Document.

15. All product data for the H2S, such as PMSM extrusion force improvement and model print times, is based on Bambu Lab's internal testing. Actual results may vary due to individual product differences, user habits, and environmental conditions. Please refer to actual usage for reference.

16. Big thanks to everyone who created these amazing projects: Crimson Shadow, Sword of the Dark Knight, Shadowforged Armor @sarwtin; Pacific Clipper @Rarecho Studio; CyberTrack @CyberBrick™; Truck, Sport Car @SophieBigRat @jinghai; MODCASE HYPER @HaydnBao; Fishcaster-Lite Electric Guitar @user_2955528674 (翻滚吧咸鱼); Storage Toolbox @schuylab; Standard Gridfinity Bin Set @Finneas; Go-Kart @2040085396 (大琢磨); "Growing Taller" Small Bag @ricky.svg; Self Watering Seed Starter @Meyui; Small FPV Aircraft @LaoYan FPV; Classic Roadster @21CNCStudio; Pen Holder @yanribing; Folding Wooden Box @woodbear; Round Box @brandon8747; Candy Carrying Tricycle @garagem 167; Floral Keepsake Box @MetaImi; Football Helmet @animuL67; Side Table @AEKI; Mini Catmaw - CyberBrick Edition @polymech3d; The Grand Budapest Hotel @雅杰不加班

Specifications

Printing Technology

Fused Deposition Modeling

Body

Build Volume (W*D*H)

340*320*340 mm³

Chassis

Aluminum, Steel, Plastic and Glass

Laser Safety Windows

Equipped on Laser Edition, normal H2S can upgrade through Laser Upgrade Kit

Air Assist Pump

Equipped on Laser Edition, normal H2S can upgrade through Laser Upgrade Kit

Physical Dimensions

492*514*626 mm³ (Package size: 620*620*755 mm³)

Net Weight

H2S Laser Edition: 30.5 kg

(Gross weight: H2S Laser Full Combo: 45.8 kg)

Toolhead

Hotend

All Metal

Extruder Gear

Hardened Steel

Nozzle

Hardened Steel

Max Nozzle Temperature

350 °C

Included Nozzle Diameter

0.4 mm

Supported Nozzle Diameter

0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm

Filament Cutter

Built-in

Filament Diameter

1.75 mm

Extruder Motor

Bambu Lab High-precision Permanent Magnet Synchronous Motor

Heatbed

Supported Build Plate Type

Textured PEI plate, Smooth PEI Plate

Max Heatbed Temperature

120 ℃

Speed

Max Speed of Toolhead

1000 mm/s

Max Acceleration of Toolhead

20,000 mm/s²

Max Flow for Hotend (Standard Flow Hotend)

40 mm³/s (Test parameters: 250 mm round model with a single outer wall; Bambu Lab ABS; 280 °C printing temperature)

Max Flow for Hotend (Optional High Flow Hotend)

65 mm³/s (Test parameters: 250 mm round model with a single outer wall; Bambu Lab ABS; 280 °C printing temperature)

Chamber Temperatur Control

Active Chamber Heating

Supported

Max Temperature

65 °C

Air Purification

Pre-filter Grade

G3

HEPA Filter Grade

H12

Activated Carbon Filter Type

Granulated Coconut Shell

VOC Filtration

Superior

Particulate Matter Filtration

Supported

Cooling

Part Cooling Fan

Closed Loop Control

Cooling Fan for Hotend

Closed Loop Control

Main Control Board Fan

Closed Loop Control

Chamber Exhaust Fan

Closed Loop Control

Chamber Heat Circulation Fan

Closed Loop Control

Auxiliary Part Cooling Fan

Closed Loop Control

Supported Filament Type

Supported Filament Type

PLA, PETG, TPU, PVA, BVOH, ABS, ASA, PC, PA, PET, PPS;

Carbon/Glass Fiber Reinforced PLA, PETG, PA, PET, PC, ABS, ASA, PPA, PPS

Sensor

Live View Camera

Built-in; 1920*1080

Toolhead Camera

Built-in; 1600*1200

BirdsEye Camera

Built-in; 3264*2448(Equipped with Laser Edition)

Door Sensor

Supported

Filament Run Out Sensor

Supported

Filament Tangle Sensor

Supported

Filament Odometry

Supported with AMS

Power Loss Recovery

Supported

Electrical Requirements

Voltage

100-120 VAC / 200-240 VAC, 50/60 Hz

Max Power¹

2050 W@220 V / 1170 W@110 V

Working Temperature

10 °C-30 °C

Electronics

Touchscreen

5-inch 720*1280 Touchscreen

Storage

Built-in 8 GB EMMC and USB Port

Control Interface

Touchscreen, mobile App, PC App

Neural Processing Unit

2 TOPS

Software

Slicer

Bambu Studio Supports third-party slicers which export standard G-code, such as Super Slicer, PrusaSlicer and Cura, but certain advanced features may not be supported.

Supported Operating System

MacOS, Windows, Linux

Wi-Fi

Operating Frequency

2412-2472 MHz (CE/FCC), 2400-2483.5 MHz (SRRC), 5150-5850 MHz

Wi-Fi Transmitter Power (EIRP)

2.4 GHz: <23 dBm (FCC); <20 dBm (CE/SRRC/MIC)

5 GHz Band1/2: <23 dBm (FCC/CE/SRRC/MIC)

5 GHz Band3: <30 dBm (CE); <24 dBm (FCC)

5 GHz Band4: <23 dBm (FCC/SRRC); <14 dBm (CE)

Wi-Fi Protocol

IEEE 802.11 a/b/g/n

10W Laser Module

Laser Type

Semiconductor Laser

Laser Wavelength

Engraving Laser: 455 nm ± 5 nm Blue Light

Height Measuring Laser: 850 nm ± 5 nm Infrared Light

Laser Power

10 W ± 1 W

Laser Spot Dimension

0.03 * 0.14 mm²

Working Temperature

0 °C-35 °C

Max Engraving Speed

400 mm/s

Max Cutting Thickness

5 mm (Basswood Plywood)

Laser Safety Class for Laser Module

Class 4

Overall Laser Safety Class²

Class 1

Engraving Area

H2D: 310 * 270 mm²

H2S: 310 * 260 mm²

XY Positioning Method

Visual Positioning

XY Positioning Accuracy

< 0.3 mm

Z Height Measuring Method

Micro Lidar

Z Height Measuring Accuracy

± 0.1 mm

Flame Detection

Supported

Temperature Detection

Supported

Door Sensor

Supported

Laser Module Installation Detection

Supported

Safety Key

Included

Air Pump

Built-in; 30 kPa, 30 L/min

Ventilation Pipe Adapter Outer Diameter

100 mm

Supported Material Type

Wood, rubber, metal sheet, lether, dark acrylic, stone, and more

Cutting Module

Cutting Area

H2D:300*285 mm²

H2S:297.5*300 mm²

Drawing Area

300*255 mm²

Supported Pen Diameter

10.5 mm-12.5 mm

Cutting Mat Type

LightGrip and StrongGrip Cutting Mats

Blade Type

45°*0.35 mm

Blade Pressure Range

50 gf-600 gf

Max Cutting Thickness

0.5 mm

Blade and Pen Recognition

Supported

Cutting Mat Type Detection

Supported

Supported Image Type

Bitmap and Vector Images

Supported Material Type

Paper, PVC, vinyl, leather, and more

Note

¹ To ensure the heatbed quickly reaches the needed temperature, the printer will maintain maximum power for about 3 minutes.

² When the printer's protection is complete and properly working, the printer and laser module work as a class 1 laser product.