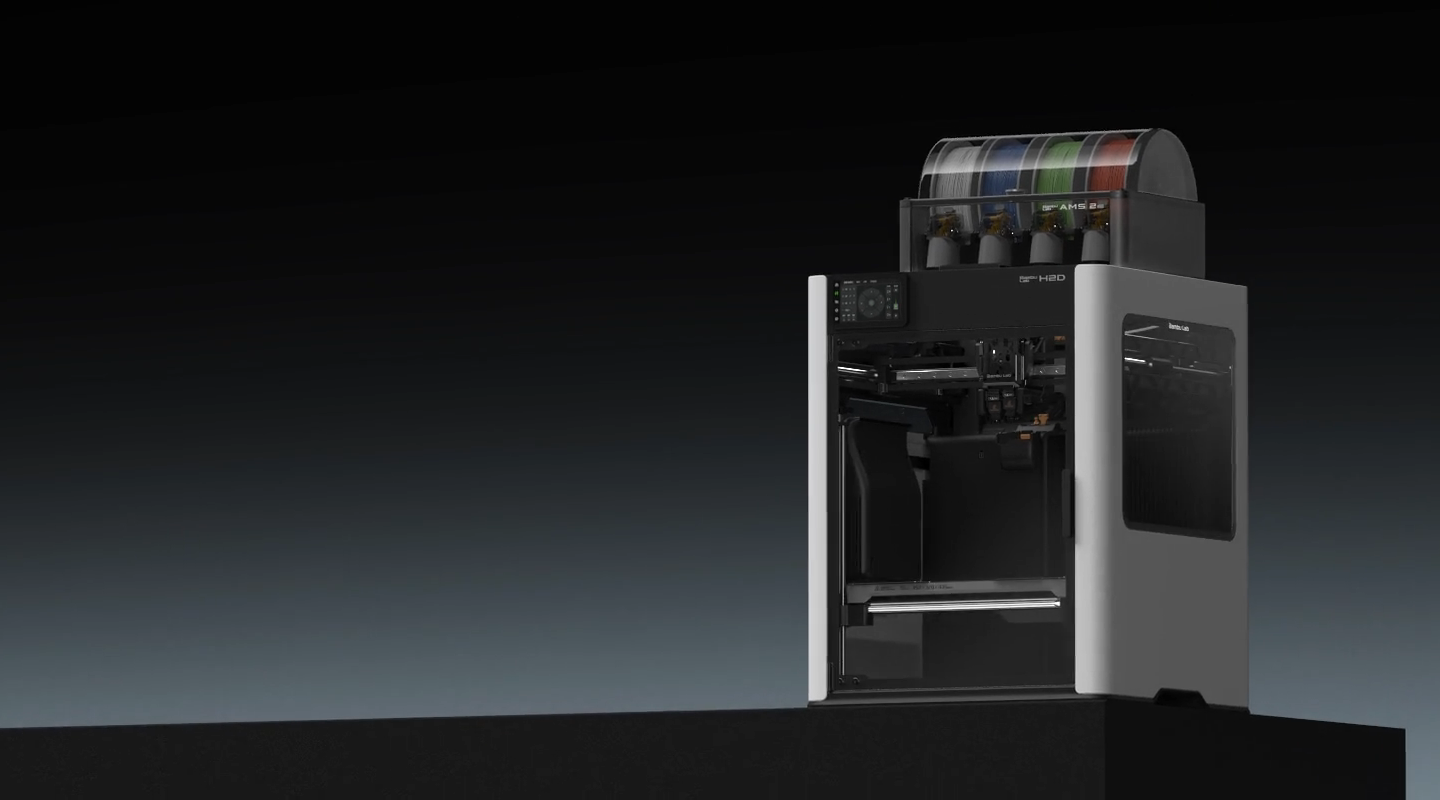

Bambu Lab H2D Engineering Bundle Combo Pack AMS 2 Pro & AMS HT Included

Build Size 350 x 320 x 325 mm, Dual-nozzle Multi-material 3D Printing 5m Resolution Optical Motion Calibration Closed-loop Servo Extruder

Bambu Lab H2D Engineering Bundle Combo Pack AMS 2 Pro & AMS HT Included

Build Size 350 x 320 x 325 mm, Dual-nozzle Multi-material 3D Printing 5m Resolution Optical Motion Calibration Closed-loop Servo Extruder

- Brand: Bambu Lab

- MPN: PF003-D+SA007+SA008-AU

- Part #: PTRBAM0022

- UPC:

- Brand: Bambu Lab

- MPN: PF003-D+SA007+SA008-AU

- Part #: PTRBAM0022

- UPC:

Similar in-stock products available at PB Tech right now

Features

Specifications

Reviews

Delivery & Pick-up

Returns & Warranty

Popular 3D Printers

Bambu Lab H2D Engineering Bundle Combo Pack AMS 2 Pro & AMS HT Included Build Size 350 x 320 x 325 mm, Dual-nozzle Multi-material 3D Printing 5m Resolution Optical Motion Calibration Closed-loop Servo Extruder

- Brand: Bambu Lab

- MPN: PF003-D+SA007+SA008-AU

- Part #: PTRBAM0022

Product URL: https://www.pbtech.co.nz/product/PTRBAM0022/Bambu-Lab-FDM-3D-Printer-H2D-Engineering-Bundle-Co

| Branch | New Stock | On Display |

|---|---|---|

| Auckland - Albany | 0 | |

| Auckland - Glenfield | 0 | |

| Auckland - Queen Street | 0 | |

| Auckland - Auckland Uni | 0 | |

| Auckland - Westgate | 0 | |

| Auckland - Penrose | 0 | |

| Auckland - Henderson (Express) | 0 | |

| Auckland - St Lukes | 0 | |

| Auckland - Manukau | 0 | |

| Hamilton | 0 | |

| Tauranga | 0 | |

| New Plymouth | 0 | |

| Palmerston North | 0 | |

| Petone | 0 | |

| Wellington | 0 | |

| Auckland - Head Office | 0 | |

| Auckland - East Tamaki Warehouse | 0 | |

| Christchurch - Hornby | 0 | |

| Christchurch - Christchurch Central | 0 | |

| Dunedin | 0 |

Features

NOTE: This is a bundle combo pack including H2D, AMS 2 Pro and AMS HT.

Bambu Lab H2D

Rethink Personal Manufacturing

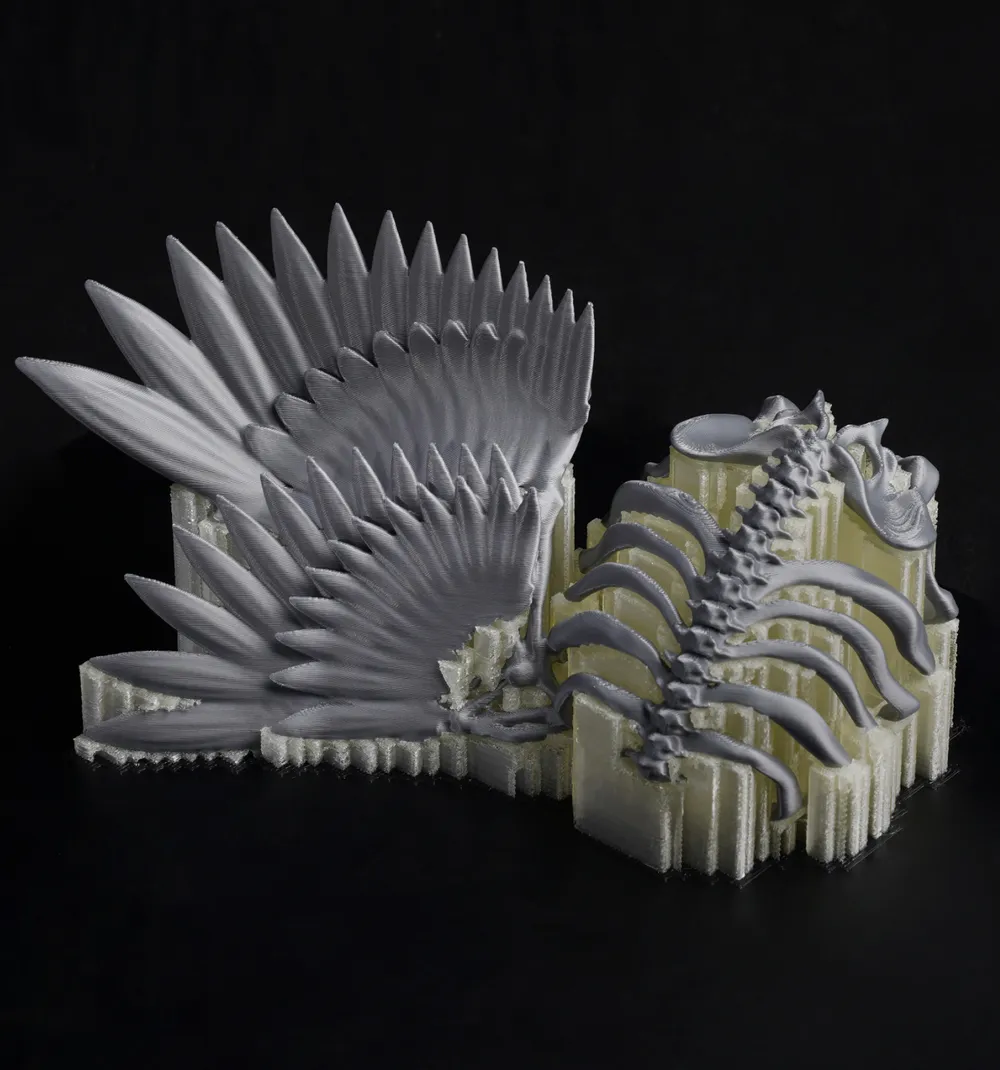

Multi-material Printing - Flexible and rigid, low cost and exotic materials in one print

Combine flexible and rigid materials in a single print to create impressive interlocking structures and innovative designs beyond traditional manufacturing. Pairing high-performance materials with standard ones further reduces costs and boosts material efficiency by using premium materials only where necessary.

Dedicated Support Material - Perfect supports with minimal waste, purging and reloading

Print with support is no longer a headache. With H2D's dual-nozzle setup, one nozzle can be reserved for dedicated support material, allowing secured print and perfect support interface.

Efficient Multi-color Printing - Fast and efficient multi-color printing

Dual-nozzle printing reduces purge cycles in multi-color prints. H2D's smart algorithms optimize filament use, maximizing dual-nozzle efficiency to save time and materials.

King-size Work Zone - Break free from size constraints

With a print volume up to 350mmx320mmx325mm*, creating large-scale projects has never been easier! From laser engraving on sizable objects to printing oversized models, the expanded capacity empowers you to bring even your most ambitious ideas to life.

Max

Single-nozzle

Dual-nozzle

X1C

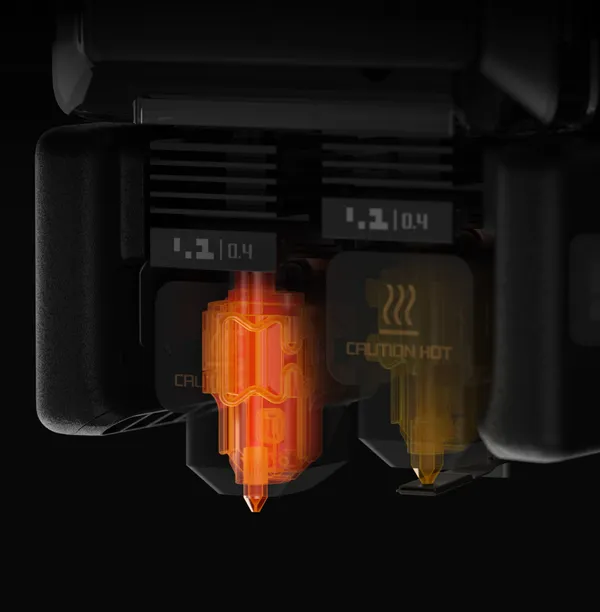

350°C Hotend & 65°C Chamber Heating - Unleash the full potential of high-performance materials

Equipped with 65°C active chamber heating and a high-temperature hotend reaching up to 350°C, the H2D delivers precise closed-loop temperature control. This advanced system effectively eliminates warping and deformation in high-performance materials, ensuring superior layer bonding and maximizing their full potential.

High-temp Hotend

Chamber Heating

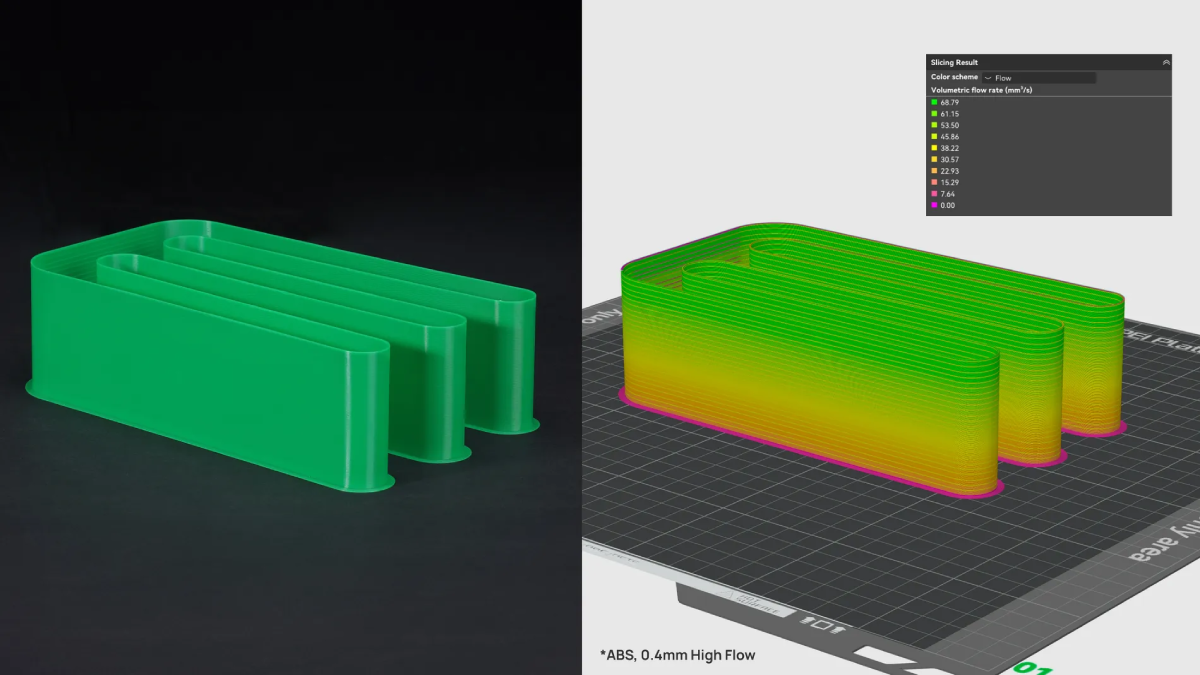

REAL High-Flow Hotend* - Consistently print at 600mm/s with ease

The H2D's purpose-built high-flow hotend ensures reliable, high-speed printing at 600mm/s. Designed for consistent performance, it eliminates mid-print flow rate restrictions, enabling uninterrupted high-speed printing regardless of the print size or complexity.*

DynaSense Extruder - Intelligent sensing for precise extrusion control

Bambu Lab's proprietary PMSM servo architecture establishes an intelligent extrusion governance system. It executes 20kHz Torque/Resistance and position sampling to dynamically modulate electromagnetic torque vectors. Stabilizing extrusion and detecting filament grinding and clogging.

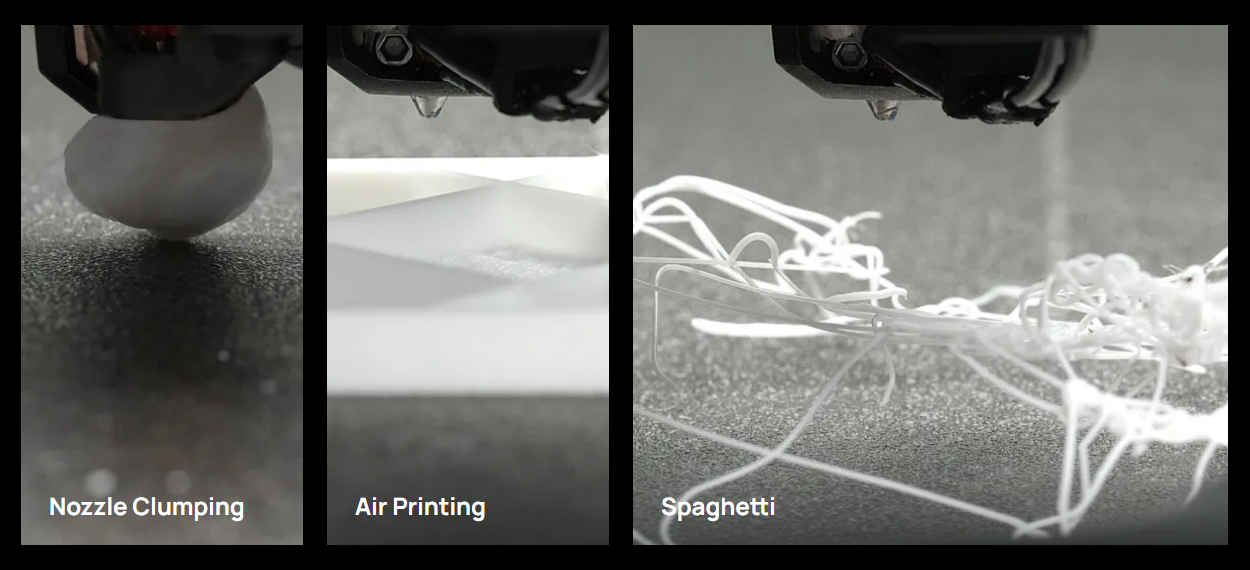

Nozzle Camera - Monitor extrusion at the nozzle tip

The H2D features an AI-backed nozzle camera with macro lens. This intelligent monitoring system continuously tracks extrusion patterns, immediately detecting material accumulation, filament deviations, and extrusion failures.

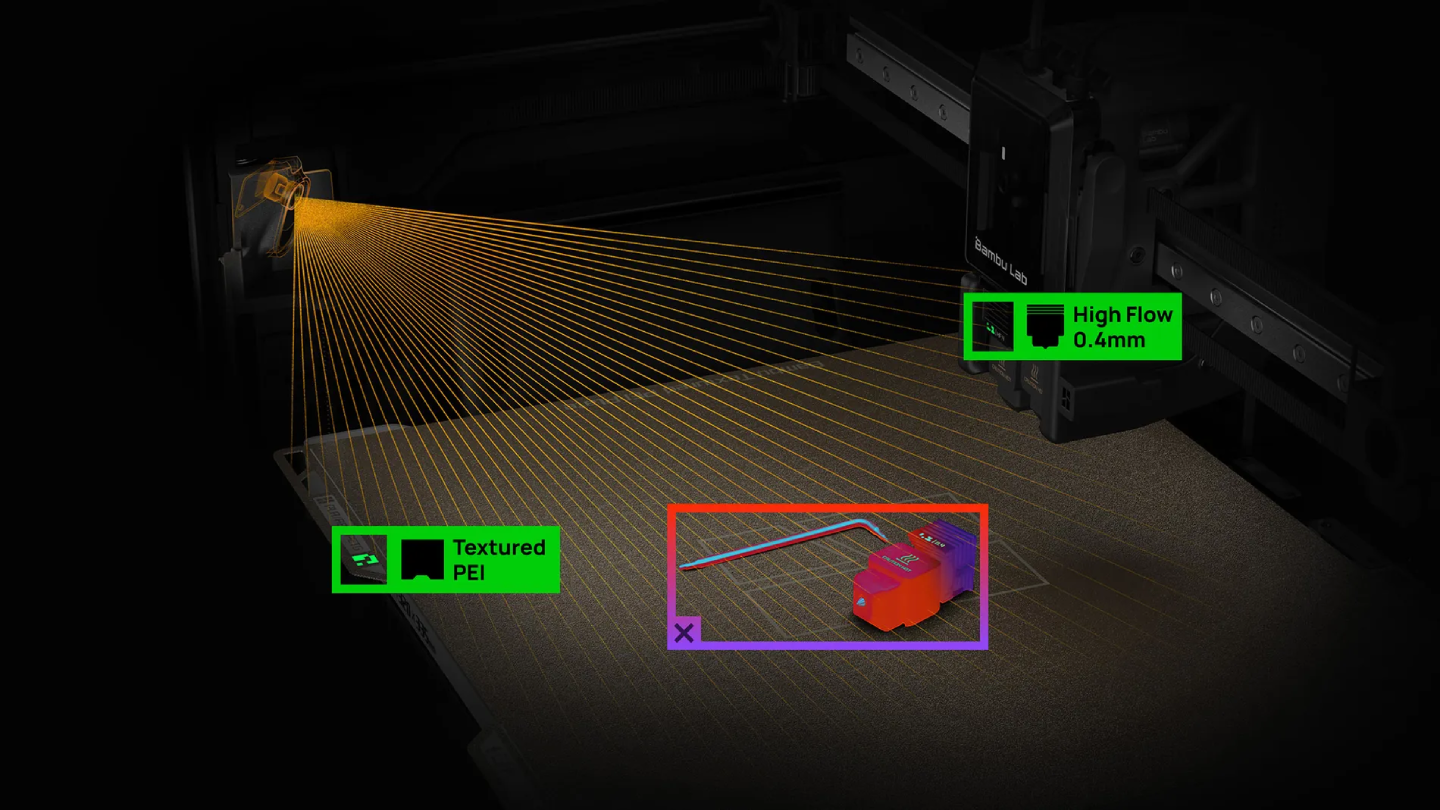

Pre-Flight Checklist by Al - Peace of mind, every time you print

Prior to each operational cycle, H2D's vision system initiates a comprehensive pre-flight checklist: Chamber Integrity Scan - Detects debris across the entire print surface. Hardware Configuration Audit - Instantly identifies nozzle dimensions and build plate properties. Digital-Physical Alignment - Automatically verifies consistency between detected hardware specifications and active slicer parameters.

SOTA Filament Monitoring - 15 sensors on one filament path

Unlike legacy systems with single filament run-out detectors, the H2D features comprehensive material flow monitoring. Throughout the AMS-to-nozzle path, 15 strategic sensors form an intelligent network, continuously tracking five key parameters: feeding velocity, tension, filament tip location, extruder thermal environment, and dynamic extrusion pressure. This establishes an industry-leading filament behavior control system.

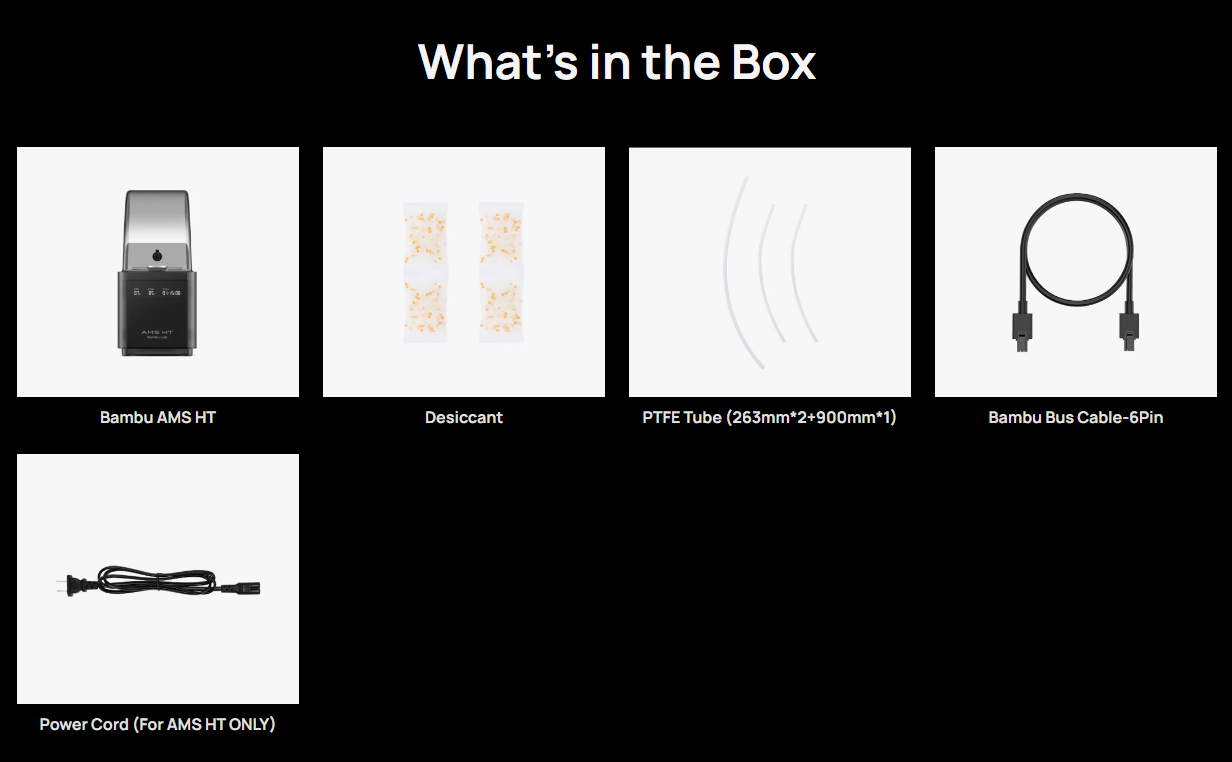

What's in the Box

Product Features:

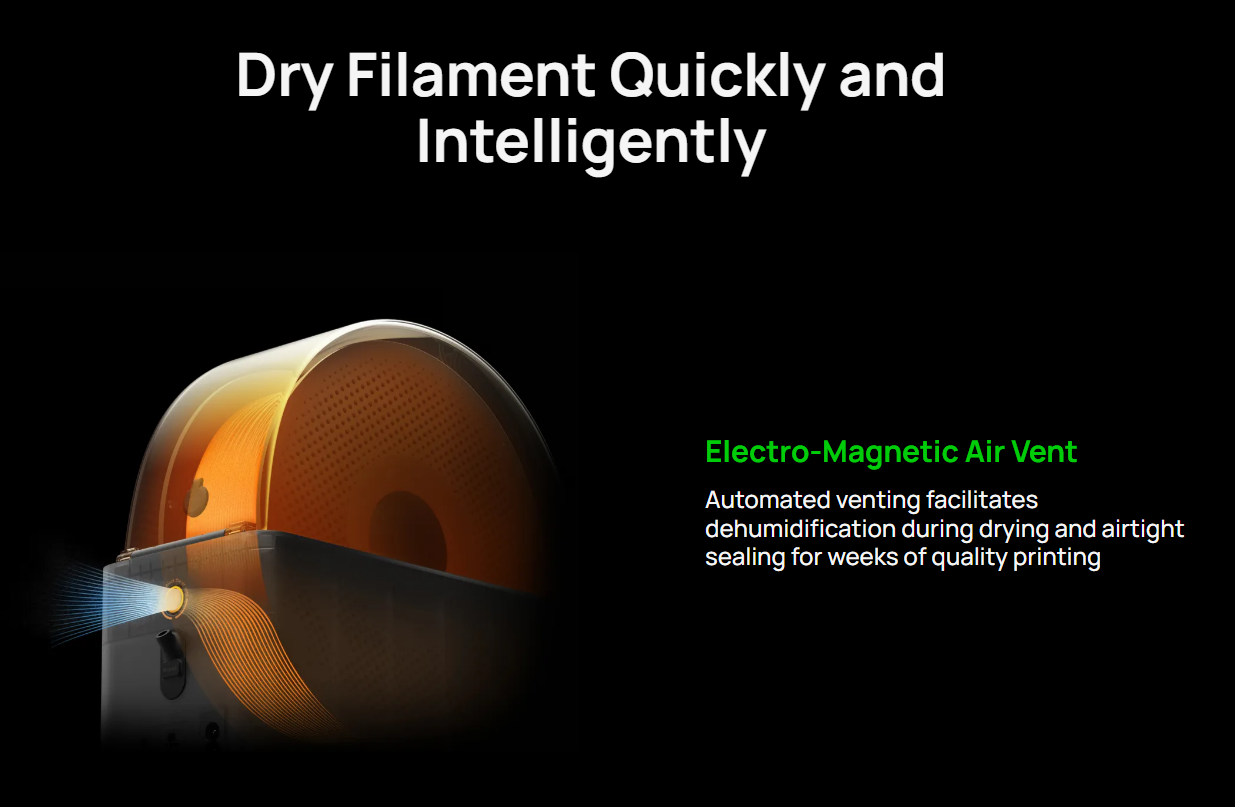

- Active Air Vent 85°C Filament Drying

- Air-tight Filament Storage

- Up to 24-color/Multi-material Printing

- Brushless Servo Feeding Motor

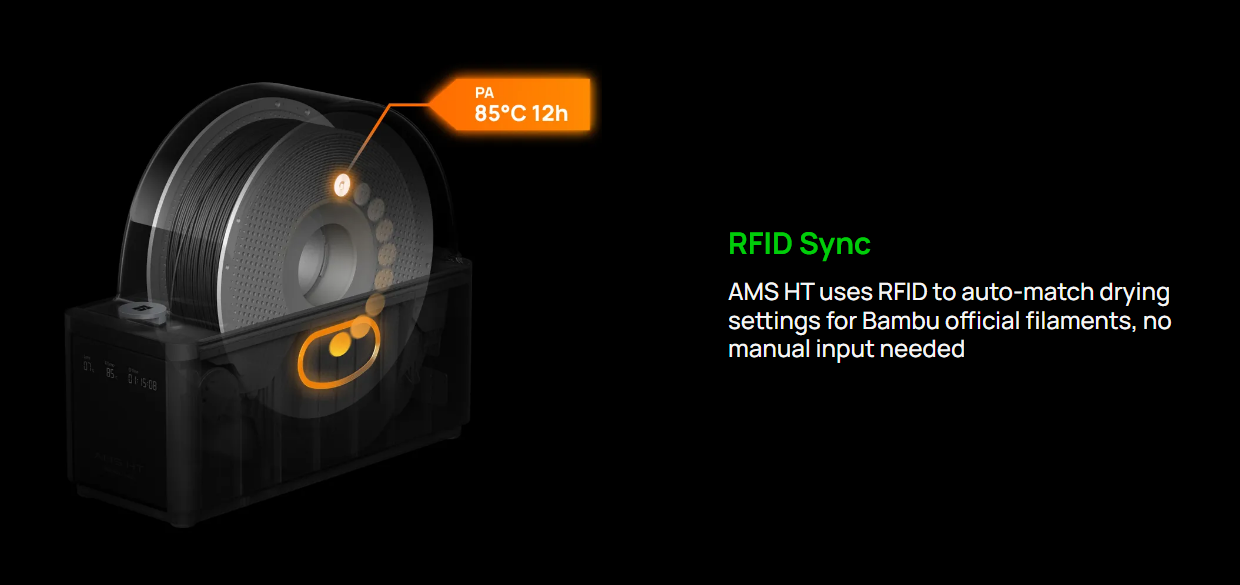

- RFID Filament Sync

- AMS HT compatibility with A1/A1 mini printers will be added through an OTA update in Q3 2025

- AMS HT is temporarily not compatible with X1E

AMS HT Specs

Explore more about AMS HT

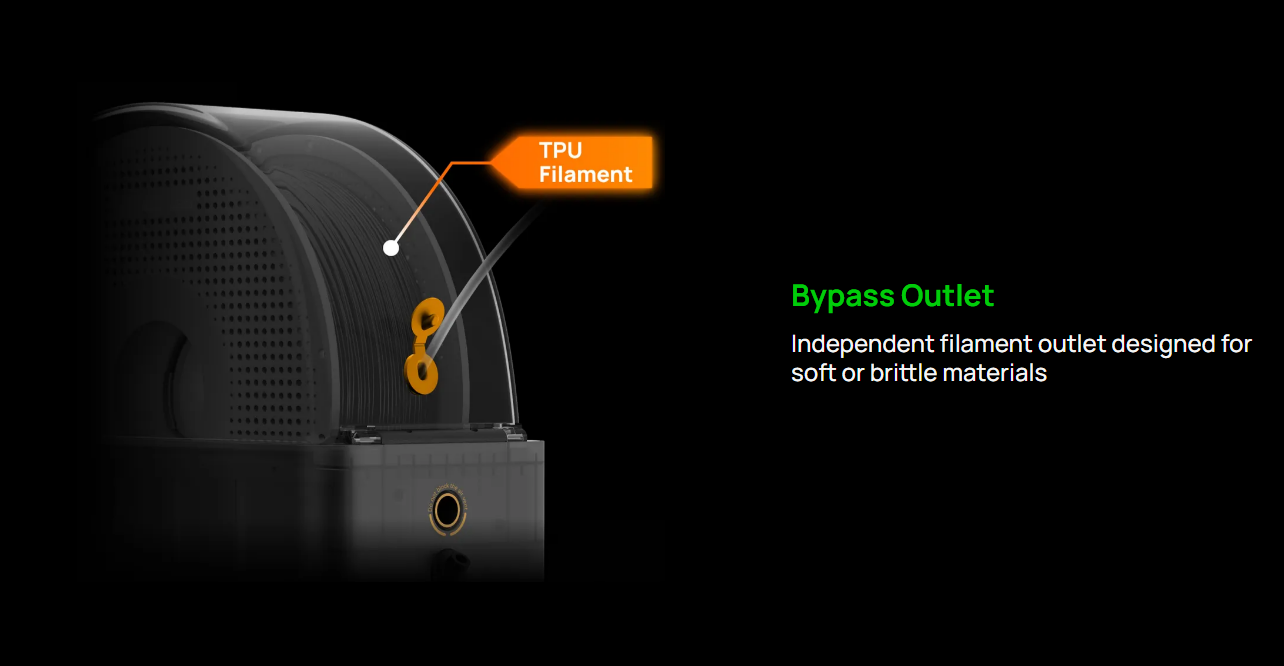

1.What is the difference between the two discharge ports on the back of the machine?

The port at the rear of the top cover is specifically for TPU filament. Due to the softness of the TPU filament, it is easy to fail when using the AMS 2 Pro automatic feeding function. When using the TPU, insert it into the AMS HT and ensure the material tray rotates in the correct direction. Insert the material tube into the TPU output port and manually push the filament through the PTFE tube until it is fully loaded into the extruder.

Note:

1.When using TPU, AMS HT cannot use the automatic feed and return function, but can be used as a drying box to prevent material moisture.

2.AMS HT won't be able to run filament drying while feeding filament and initiating a print via the bypass port.

2.Can the AMS HT be used with the X series and P series printers?

If only connecting one AMS HT to an X or P series printer, the PTFE tube coupler, 4-pin cable and Filament Buffer are required. If connecting multiple AMS HT units, we recommend that you purchase an AMS Hub.

AMS HT compatibility with A1 and A1 mini printers will be added through an OTA update in Q3 2025.

For more information please refer to: wiki.

3.Can I print and dry at the same time?

Printing while drying is not yet supported, including all the AMSs that are related to the on-going print job (eg. The AMSs assigned for auto-refill). However, you can dry filament in AMSs that are not assigned to the on-going print job.

4.How many AMS HT units can be connected to the X1 series and P1 series at most?

X1 and P1 series printers support up to 4 AMS HT connections at the same time.

5.Can the AMS HT be directly connected to the printer for drying?

H2D and X/P/A series printers are connected to AMS HT and use drying function. Each AMS HT requires an external 220V power supply for drying It is not supported to draw power from the printer for drying (The power adapter is pre-included with the product package).

6.Does it support standalone drying without connecting to the printer?

When using the AMS HT drying function, the AMS HT must be connected to the printer via a 6-pin bus cable to ensure that the printer is powered on and set to filament drying mode.

The AMS HT cannot perform standalone drying without a connection to the printer.

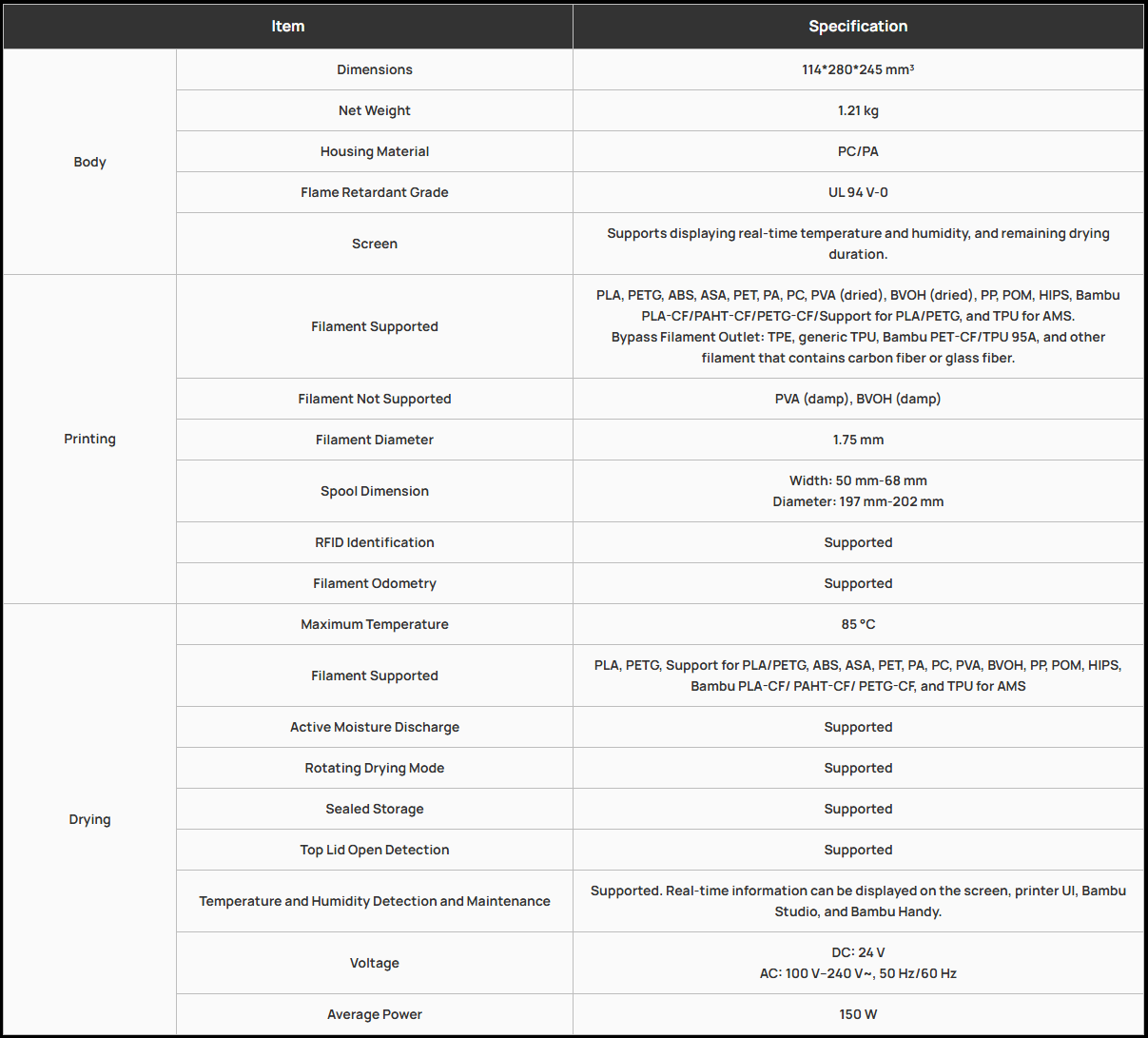

Specifications

Body

Dimensions

114*280*245 mm3

Net Weight

1.21 kg

Housing Material

PC/PA

Flame Retardant Grade

UL 94 V-0

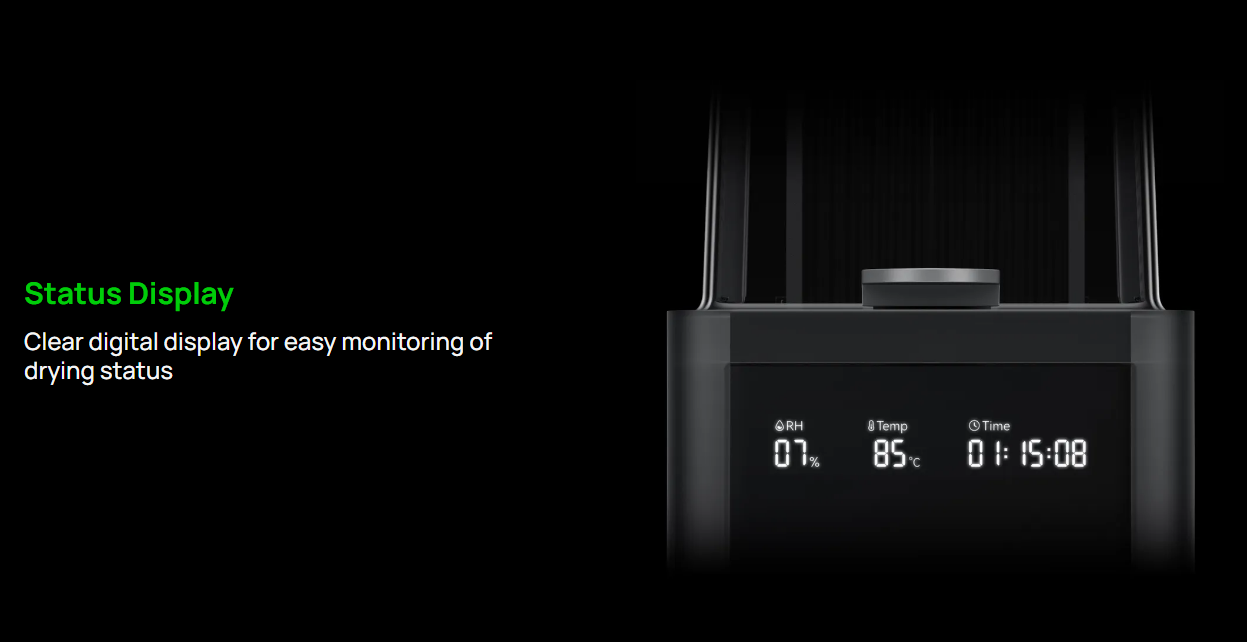

Screen

Supports displaying real-time temperature and humidity, and remaining drying duration.

Printing

Filament Supported

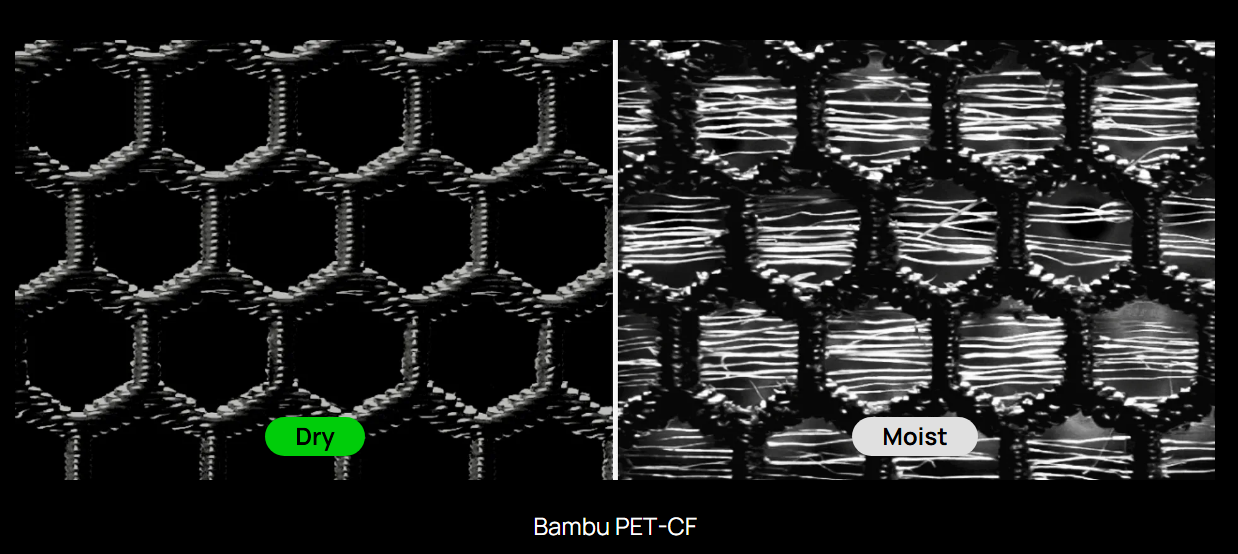

PLA, PETG, ABS, ASA, PET, PA, PC, PVA (dried), BVOH (dried), PP, POM, HIPS, Bambu PLA-CF/PAHT-CF/PETG-CF/Support for PLA/PETG, and TPU for AMS.

Filament Not Supported

PVA (damp), BVOH (damp)

Bypass Filament Outlet

TPE, generic TPU, Bambu PET-CF/TPU 95A, and other filament that contains carbon fiber or glass fiber.

Filament Diameter

1.75 mm

Spool Dimension

Width: 50 mm-68 mm

Diameter: 197 mm-202 mm

RFID Identification

Supported

Filament Odometry

Supported

Drying

Maximum Temperature

85 °C

Filament Supported

PLA, PETG, Support for PLA/PETG, ABS, ASA, PET, PA, PC, PVA, BVOH, PP, POM, HIPS, Bambu PLA-CF/ PAHT-CF/ PETG-CF, and TPU for AMS

Active Moisture Discharge

Supported

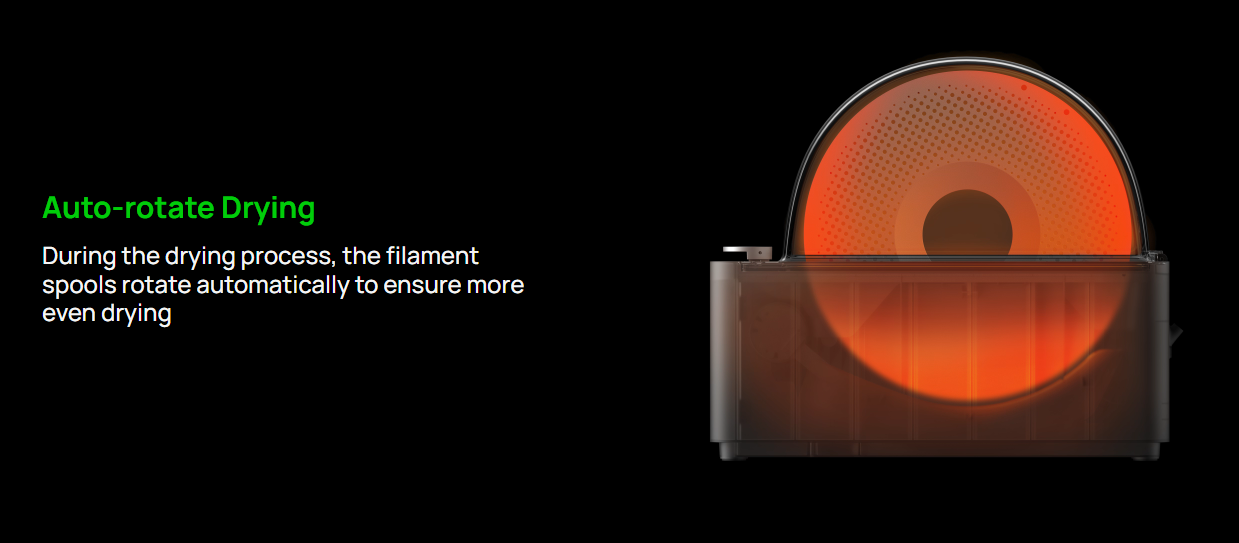

Rotating Drying Mode

Supported

Sealed Storage

Supported

Top Lid Open Detection

Supported

Temperature and Humidity Detection and Maintenance

Supported. Real-time information can be displayed on the screen, printer Ul, Bambu Studio, and Bambu Handy.

Voltage

DC: 24 V

AC: 100 V-240 V~, 50 Hz/60 Hz